Listing ID #184599

Company Information

Ask for more detail from the seller

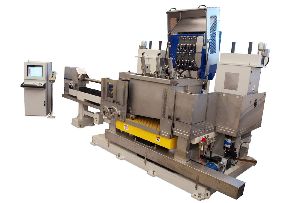

Contact SupplierWe are offering label inspection system.

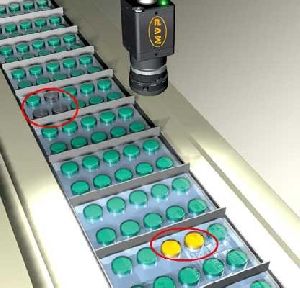

Our clients can avail from us label inspection system. The vision system is used in production line for the 100% quality assurance. It inspects for visible defect in the productprinting at high speed. Vision inspection is completely replacing manual inspection using higher accuracy and higher speed compare to manual inspection.

applications

this system is mainly used for quality assurance in pharmaceutical industry, food & beverage industry, cosmetic products industry, printing press industry, packaging industry etc. The different applications of system includes :

technical specifications

industries where this product is used

features