Listing ID #224697

Company Information

Ask for more detail from the seller

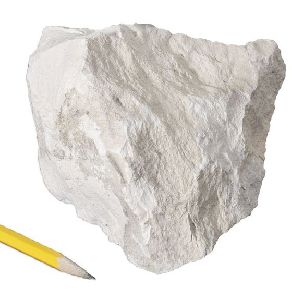

Contact SupplierSteel manufacturers prefer dolomite of the following composition for dead burning:

MgCO3 - 35% Min.

SiO2 - 1% Max.

Fe2O3+Al2O3 - 1.5% Max.

CaCO3 - Remainder

Dolomite for use as flux in steel metallurgy should be hard, compact and fine-grained so that it can stand the burden of the batch in the blast furnace as well as the basic steel convertor. It should not be crystalline, i.e., it should not have a saccharoidal texture which gives fritting effect in the furnace. Impurities as low as possible are preferred. It should be free from phosphorous and sulphur. Generally, two grades of dolomite are used, one is called blast furnace (BF) grade and the other steel melting shop (SMS) grade.

The dolomite containing insolubles (Al2O3+Fe2O3+SiO2) upto 7%, is used in the blast furnace by most of the steel manufacturers in the country but the dolomite dontaining a maximum of 4 to 5% insolubles is preferred. Silica and alumina contents in dolomite are not regarded deleterious for blast furnaces. They only cause unnecessary increase in the slag. Dolomite has been found as a useful support to limestone in removing sulphur from the iron ore. It also reduces the viscosity of the slag, thus chemical reactions in the furnace. For the steel melting shop the total insolubles below 4% are preferred. The silica content should be as low as possible, in no case above 2% being tolerated.

The ferro-manganese manufacturers in India usually prefer SMS dolomite for fluxing purposes.

In general, the metallurgical industries require dolomite of the following grades for fluxing purposes.