Related Category

Business Type

Steel Round Grey Polished spiral compression springs

4 - 4 /Piece

Super Springs India

Metal Round Metallic Polished 2nd stage air compressor valve spring

380 - 480 /piece

Mauli Enterprises

81 /Kilogram

Shark Steels

Metal Round Available In Different Colors Non Polished Polished Compression Springs

1 - 850 /PC

RIDON AUTO PARTS COMPANY

800 /Piece

Bhagirthee Refrizretion Works

Spring Steel Round Polished Dale grey shocker springs

22 /Piece

Dale Filter Systems Pvt. Ltd.

Round Shiny Silver Phosphated Copper conical spring washer

5 /Piece

M.I. Industrial Suppliers

Black M.coil Spring Conical Spring

3.50 /Piece

M. Coil Spring Manufacturing Company

1,850 /Piece

Venus Spring Manufacturing

250 /Piece

Fitwell Engineers

Spring Steel Round Grey Polished weir spm plunger valve springs

50 - 51 /Piece

Astarn Engineering and Oilfield Supplies Pvt. Ltd.

MS Powder Coating Round Black New mahindra bolero vtx front suspension coil spring

2,550 /Piece

Hariram Rochiram Auto Private Limited

Get Quotes from Verified Suppliers

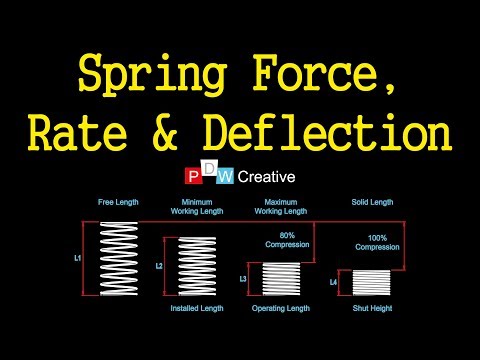

Generally, compression springs are installed over shafts or rods or into round holes in order to resist linear compression. When a spring experiences pressure from a force pressing on its axis, the spaces between the coils compress and the entire spring gets shorter. The more weight or pressure that is placed on the spring, the more strength or energy the spring has to push back. A compression spring responds to the weight suppressing it with unbendable strength in an effort to return to its initial height.

A compression spring is an open-coiled helical spring that is designed to offer resistance to a compressive force applied axially. Compression springs can be coiled in other needed forms such as conical, convex (hourglass), concave (barrel), or various combinations of these mentioned forms. Normally they are coiled at a constant diameter. These springs are utilized to resist force or store energy, depending upon the application. One can simply contact the leading compression springs suppliers and compression spring exporters in the market to get the superior quality compression springs for sale at a most effective rate.

Get Quotes from Verified Suppliers

Springs are mechanical devices that have the ability to store mechanical energy because of their elasticity. Springs are basically made up of coiled, hardened steel, although non-ferrous metals such as titanium, bronze, and even plastic are also used for fabrication. There are various types of springs available in the market, designs of which take advantage of different energy storage management. They are as follows:

The compression springs exporters and compression springs suppliers in the market are instrumental in presenting a wide array of compression springs for their valuable customers as per their requirements. The compression springs for sale provided by them are extremely strong and are designed and manufactured in countless sizes. That’s why, compression springs are ideal for a varied range of applications like pens, couches, pogo sticks, mattresses, locks, medical devices, automobile suspension, and much more.

The highest grades of spring wire are used by the compression spring manufacturers when fabricating the compression springs. The most common material types used by the compression spring manufacturers for compression springs are stainless steel (type 302, type 316 and type 17-7 PH), music wire, hard drawn, chrome silicon, and phosphor bronze. With the varied selection of springs and wire forms and the industry expertise, the compression spring manufacturers can create intricate custom springs. The most common compression spring materials include:

The compression spring suppliers or compression spring manufacturers use state-of-the-art CNC coiling machines with in-line monitoring cameras and sorters. Their in-line cameras and sorters monitor the outside diameter and free length of each spring and sort out any springs that are out of tolerance. They grind the ends of compression springs if ground ends are required.

One can find compression springs for sale in different shapes. The parameter that differs from one shape to the next is the outside diameter of the spring.

The compression spring manufacturers involved in offering custom compression springs to meet the 100% satisfaction of their clients. The custom compression spring presented by the top compression spring manufacturers include: