Listing ID #60595

Company Information

Ask for more detail from the seller

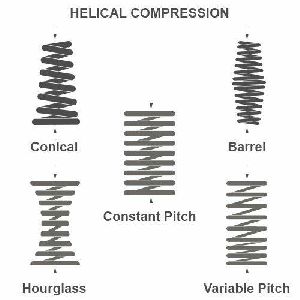

Contact SupplierNew materials, technical innovations and our experience has resulted in the advanced new product of Helical Coil Spring. We are a well renowned name in manufacturing and exporting of Helical Coil Spring. With our reasonable prices we offer you to purchase excellent quality product.

Features:

Formation : Constant Diameter Cylindrical type and Conical type.