Listing ID #4922330

Company Information

Ask for more detail from the seller

Contact Supplier| Description | ||

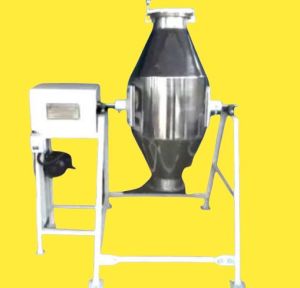

| The Double Cone Blender is an efficient and versatile machine for mixing dry powder and granules homogeneously. All the contact parts made out of stainless steel of required grade by customer. Two third of the volume of the Cone Blender is filled to ensure proper mixing. It can be used for Pharmaceutical, Food, Chemical and Cosmetic products etc. | ||

| Salient Features | ||

| The conical shape at both ends enables uniform mixing and easy discharge. | ||

| All contact parts are made out of Stainless Steel 304 or 316 quality material as required by customer. | ||

| Maximum care has been taken to ensure safe operation of the unit. | ||

| Manual rotating facility with hand wheel for inching. The same will be provided with Stainless Steel cover & limit switch. (In 200 Kgs. & above model) | ||

| Two nos. of safety road will be provided at back side. ( One LH side & one RH side ) | ||

| Suitable size of butter fly valve at one end of the cone provided for material discharge & hole with openable cover provided at other end of the cone for material charging & cleaning. | ||

| One shaft with 04 nos. of fixed buffels with mirror polished provided inside the cone. | ||

| Cone will be mirror polished from the inside & outside & structure will be matt polished. | ||

| All moving parts covered with SS304 covers. | ||

| Safety guards made from SS304 pipes provided in front of the m/c with limit switch. | ||

| Panel fabricated from SS304 material with facility of three phase indication, D.O.L. starter, digital timer & Amp. Meter. | ||

| As per customer requirement machine will be provided with left side drive or with right side drive. | ||

| The conical shape at both ends enables uniform mixing and easy discharge. | ||

| All contact parts are made out of SS304/316(as per customer requirement) quality material. | ||

| Maximum care has been taken to ensure safe operation of the unit. | ||

| Worm reduction gear use for speed reduction. | ||

| Food grade rubber gasket will be used on both end of cone as well as in butterfly valve. | ||

| Inside & outside of the cone will be polished to the mirror finished. | ||

| General structure made out of SS304 and Polished to the matt / mirror finish ( as required by you ) in GMP Model. | ||

| All safety guards & covers made out of SS304 in GMP Model. | ||

| Hand wheel will be provided for manual tilting of cone. | ||

| Safety guards provided with limit switch to not start the machine when safety guards are not in proper position. | ||

| Model No. | Gross Capacity In Ltrs. | Working Capacity In Ltrs. | Overall Dimensions (in mm) (L) x (W) x (H) | Discharge Height | Charge Opening | Power Supply |

| DCB-5 | 16 Ltrs | 10 Ltrs | 750 580 650 | 300 | 100 | 0.5 HP |

| DCB-10 | 35 Ltrs | 20 Ltrs | 1100 450 1200 | 300 | 100 | 0.5 HP |

| DCB-25 | 80 Ltrs | 50 Ltrs | 1200 600 300 | 450 | 150 | 1.0 HP |

| DCB-50 | 150 Ltrs | 100 Ltrs | 1400 800 1500 | 450 | 150 | 2.0 HP |

| DCB-100 | 300 Ltrs | 200 Ltrs | 1850 900 1900 | 450 | 200 | 2.0 HP |

| DCB-150 | 470 Ltrs | 300 Ltrs | 2000 1100 2000 | 450 | 200 | 5.0 HP |

| DCB-200 | 615 Ltrs | 400 Ltrs | 2100 1200 2100 | 450 | 200 | 6.0 HP |

| DCB-250 | 770 Ltrs | 500 Ltrs | 2200 1300 2200 | 450 | 200 | 7.5 HP |

| DCB-300 | 1000 Ltrs | 600 Ltrs | 2300 1400 2300 | 450 | 200 | 7.5 HP |

| DCB-400 | 1340 Ltrs | 800 Ltrs | 2350 1800 2350 | 600 | 250 | 7.5 HP |

| DCB-500 | 1500 Ltrs | 1000 Ltrs | 2400 1900 2400 | 800 | 250 | 10 HP |

| DCB-650 | 2000 Ltrs | 1300 Ltrs | 2800 2100 2700 | 800 | 250/400 | 10 HP |

| DCB-750 | 2500 Ltrs | 1500 Ltrs | 3000 2200 2600 | 800 | 250/400 | 10 HP |

| DCB-1000 | 3350 Ltrs | 2000 Ltrs | 3200 2300 3100 | 800 | 250/400 | 15 HP |