Welcome to ENGT

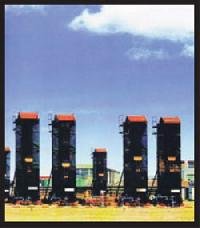

Manufacturer / Exporter / Supplier Of Drilling Rigs, Mud Pumps, Downhole Screw Meter, Rotaflex Pumping Units, Progressive Cavity Pumps, Rod Pumps, Sub-Surface Sucker Rod Pumps

Welcome to ENGT

Manufacturer / Exporter / Supplier Of Drilling Rigs, Mud Pumps, Downhole Screw Meter, Rotaflex Pumping Units, Progressive Cavity Pumps, Rod Pumps, Sub-Surface Sucker Rod Pumps

The downhole screw motor is a kind of power tool that transforms the pressure of liquid to mechanical energy in the downlole. When the power liquid flows into the screw motor, a pressure difference will be produced between the inlet and outlet of the motor, the differential pressure drives the motor rotating round the stator, provide torque moment and speed to the drill bit, thus the drilling process is being performed. The drill pipe is not rotating during work process, so the advantages are obvious if comparing with conventional drilling system. The downhole screws motor is suitable for vertical, directional and horizontal well.

The workover process of the tubing pump is as follows: firstly the barrel being connected to the tubing is directly run into the well at desired depth and then the plunger is run into the barrel with the sucker rod. The applicable tubing pump is larger in size than a corresponding rod pump typically used for the same diameter pipe, The tubing pump also has a simple structure, giving it a greater displacement and making it most suitable for shallow wells with high production. The THD type of tubing pump means that its standing valve is directly connected to the barrel and it cannot be pulled up separately with the barrel. The THC or THM type of tubing pump means that its standing valve can be pulled up separately with the barrel. The seating assembly of THC pump is cup type and for THM is mechanical type. The THC and THM type of tubing pump are suitable for the frequently work-over wells.

The rod pump is connected to the sucker rod after being assembled on the surface then it is lowered down to the well bottom through the tubing. Thus it is convenient for inspection and workover because it can be pulled up and down through the tubing and is therefore suitable for deeper well. The lifespan of the tubing can also be prolonged due to the reduction of the number of makeup cycles. The rod pump can be classified into two types: mechanical seating and cup seating. Also it is divided into three types: RHA (stationary heavy well barrel top anchor rod pump), RHB (stationary heavy well barrel bottom anchor rod pump) and RHT (traveling heavy well barrel bottom anchor rod pump).

Share your thoughts with other customers for ENGT

Add Review