Listing ID #466479

Ask for more detail from the seller

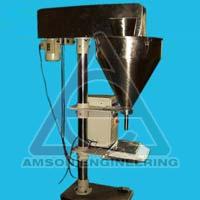

Contact SupplierWe are offering weigh filling machine.

Powder filling machines come in a wide variety of sizes, shapes, filling principles and degrees of technical sophistication in response to the ever-widening diversity of powder filling applications around. Amson’s powder filling machine is specially designed to get high accuracy outputs of powder in a limited time and thereby increase the production. For this achievement, we use digital timing mechanism assisted filling to get perfect accurate fills each time. We designed a model, where the wastage is theoretically nil and the accuracy is maximum. Hygienic and gmp standard parts assures safety for fast contaminating products.

any free flowing material, or comparatively free flowing material like flour, spice powder chemical powder, toner powder, talcum, food ingredients, food colouring agents,agro products, masala and other pharma and chemical powders can be filled very accurately by using this machine model. Accuracy this filler is very much high up to +- 1% accuracy in each filling. Speed of filling is also high, since we provide auto option for intermittent filling.

The principle of the vertical auger powder filling machine is very simple. Augur rotation creates forward movement of the material with its flights towards the filling nozzle. Each thread (flight) has a particular volume powder holding capacity as per material density. When the screw rotates, powder is taken by the screw and according to the direction of movement; it discharges the powder to the nozzle to the container or pouches.

the basic filling head comprises five primary components:

1. s.s hopper containing the powder to be dosed

2. augur or screw rotating vertically through the hopper.

3. funnel or tube outlet to hopper through which the lower parallel part of the auger doses.

4. auger (screw) drive.

5. agitation blade (stirrer) to assist powder feed properly into the flights of the augur.

structure and working:

powder filler is made strong and vibration free by its specially designed pillar structure. This is made from mild steel round pipe section of good thickness hard chrome plated, which holds drive unit, hopper and related parts. A drive motor and an electromagnetic clutch brake assembly are driving the augur. A safety cover is provided to this assembly to protect from accidents and to avoid dust from drive. Main driven shaft connected to the drive shaft through a bearing housing holds and rotates freely when the machine is operated. A stirrer blade provided separately which is operated independently over the driven shaft. The driven shaft is holding an accurately machined stainless steel augur which performs the filling inside the nozzle.

The lower parallel flights of the auger within the funnel are machined to a constant pitch so that, when filled, each pitch has a precise volume. The auger drive rotates the auger at constant speed to produce a continuous dosing flow. The agitation blade, generally separately driven and controlled, rotates in the opposite direction to the auger breaking any bridge that tends to form in non-free flowing powders. The agitation blade extends right down to the throat of the funnel preventing rat-holing and cavitations and ensuring that the flights are fully filled. The startstop signals to the auger drive control the pre-set weight in weigh metric fillers.

technical specifications afae1000:

machine size: 1050 l x 700w x 2000mm height.

machine model: afae1000- weigh based

drive motor: 1 hp 230vac 50hz, 1440 rpm. With vfd(variable frequency drive)

power : 230vac 50hz single phase

stirrer motor: 1 hp 32rpm 230vac worm geared

electromagnetic clutch- brake: hscbc 100, 24 vac cryotron make

load cell capacity: 3 kg, 100mg.

all material contact parts in s.s. 304

stainless steel 304 augur ( screw) type filling.

hopper size 45 liters (s.s 304), 18 gauge, mirror finish for afae1000

fill capacity: 50-1000 gms at a time as per set time,

additional features:

• augur based filling equipped with digital weighing unit.

• one touch start by a foot-switch

• drive through electro-magnetic clutch brake system to get high accuracy filling.

• high output and increased efficiency.

• slow speed geared motor attached to stirrer helps to feed augur uniformly

• output of 15- 20 fillsminute can be achieved.

• high accuracy up-to +- 0.5% of fill volume.

• low maintenance needed in this model.