Listing ID #930832

Company Information

Ask for more detail from the seller

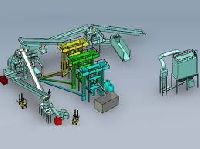

Contact SupplierWe are offering waste tyre recycling plant.

Backed by our rich industrial experience, we bring forth our customers waste tyre recycling plant. Our plant is tested on various industry set parameters so as to to ensure its high quality and fault free performance before delivering to the market. Our waste tyre recycling plant is highly acclaimed in the market for its robust construction, high speed operation, reliable performance and low maintenance. Moreover, the parts of these plants are easy to repair and replace.

some of the major features of the plant:

pyrolysis process - the perfect solution

pyrolysis process is a perfect solution for decomposition of organic compounds at raised temperatures under oxygen free (anaerobic) condition. This process produces oil, gas, carbon black and steel, and there are different phases. Industrial pyrolysis process is applied to treat rubber material and industrial plastic wastage etc.

as a result the pyrolysis process for wastage tyres produces:

fuel oil (45% - 50%),and the main oil produces by the pyrolysis process is widely used in various industrial purposes.

carbon black (30% - 35%)

pyrolysis technology produces carbon black which is the main product. It's used a lot as raw material in various industries. It also used as a rubber reinforcing agent.

Pyrolysis process produces carbon black is very economical, and thus widely used as an ingredient in various industries. It has a cost-effective advantage over conventional petroleum produced carbon black.

some of the industries where the carbon black is applicable:

steel wire (10% - 15%)

steel wires are present in tyres in a range of 10 - 15 percent. At the end of process the pyrolysis recycling process detached all the present steel in the tyres. The resultant steel wires can be used further for industrial purposes.

gas (5% to 8%)

advantages of the gases arise during the pyrolysis process: