Listing ID #3816608

Company Information

Ask for more detail from the seller

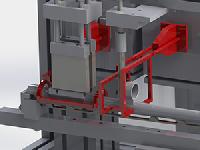

Contact SupplierArcraft is the name to turn for innovative technology. With Plasma Transferred Arc Welding we provide high productivity, high quality of powder deposits with minimum powder loss. Our advanced technology ensures significant lower cost for hardfacing , surfacing and cladding even in the most challenging area.

We are the manufacturer, supplier and exporter of Plasma Transferred Arc – PTA welding machine.

In a competition with laser surfacing the PTA technology offers much more high productivity, comparable high quality of deposits and significantly lower costs. Typical application areas of the PTA technology are:

| Model | PTA 200 | PTA 400 |

| Input | ||

| Input Supply | 415VAC / 50-60Hz / 3 - Ø | 415VAC / 50-60Hz / 3 - Ø |

| Max Installed Power (Hp) | 11 | 24 |

| Input kVA @ 60% Duty Cycle | 9.7 | 19.4 |

| Input kVA @ 100% Duty Cycle | 7.5 | 14.9 |

| Output | ||

| Open Circuit Voltage OCV (VDC) | 75 – 85 | 75 – 85 |

| Current Range (A) | 5 – 200 | 5 – 400 |

| Current @ 60% Duty Cycle (A) | 200 | 400 |

| Current @ 100% Duty Cycle (A) | 155 | 310 |

| Pilot Arc Current (A) | 10 – 25 | 10 – 25 |

| Gas Parameter | ||

| Plasma Gas Flow (LPM) | 0 – 5 | 0 – 5 |

| Shielding Gas Flow (LPM) | 0 – 10 | 0 – 10 |

| Carrier Gas Flow (LPM) | 0 – 15 | 0 – 15 |

| Pilot Parameter | ||

| Pilot Arc Current | 10 – 25 | 10 – 25 |

| Up / Down Slope (sec) | 1 – 10 | 1 – 10 |

| Pre / Post Flow (sec) | 1 – 10 | 1 – 10 |

| Programmable Parameter Welding | ||

| Gas Pre Flow (sec) | 0 – 99.9 | 0 – 99.9 |

| Gas Post Flow (sec) | 0 – 99.9 | 0 – 99.9 |

| Current Up Slope (sec) | 0 – 99.9 | 0 – 99.9 |

| Current Up Slope (sec) | 0 – 99.9 | 0 – 99.9 |

| Base Current (A) | 5 – 200 | 5 – 400 |

| Manipulator | ||

| Degree of Rotation | 0 – 360 | 0 – 360 |

| Degree of Overlap | 0 – 360 | 0 – 360 |

| Boom Step Over | 0 – 999 | 0 – 999 |

| Number of Bands | 0 – 999 | 0 – 999 |

| Rotation Speed | ||

| Boom Travel Speed | ||

| Moving Base | Optional | Optional |

| Rotating Base | Optional | Optional |

| Oscillator | ||

| Oscillation Width (mm) | 0 – 25 | 0 – 25 |

| Oscillation Per Minute | 0 – 80 | 0 – 80 |

| Dwell Time Left (sec) | 0 – 99.9 | 0 – 99.9 |

| Dwell Time Right (sec) | 0 – 99.9 | 0 – 99.9 |

| Powder Feeder | ||

| Hopper Volume (cc) | 700 | 700 |

| Powder Feed Rate | Auto w.r.t. current | Auto w.r.t. current |

| Feeder On / Off | Auto with Arc | Auto with Arc |

| Feed Slope Down | Auto w.r.t. current down slope | Auto w.r.t. current down slope |

| Water Chiller | ||

| Flow Rate (LPM) | 5 | 5 |

| Outlet Temperature (Deg C) | 10 – 30 | 10 – 30 |

| Tank Capacity (Liters) | 25 / 50 / 100 | 25 / 50 / 100 |

| Cooling Capacity (Ton) | 1 / 2 / 3 | 1 / 2 / 3 |

| Torch | ||

| Current Capacity (A) | 150 | 350 |

| Duty Cycle (%) | 100 | 100 |

| Option | ID / OD | ID / OD |

| Number of Programs | 999 | 999 |

| Hardware | ||

| Mother Board | Intel Dual Core | Intel Dual Core |

| Operating System | Embedded Microsoft XP | Embedded Microsoft XP |

| Flash Drive | ||

| PLC | 32 I / O | 32 I / O |

| Additional | ||

| Current Pre-Setting Facility | Provided | Provided |

| High Frequency Test | Provided | Provided |

| Water Failure Trip | Provided | Provided |

| Gas Failure Trip | Provided | Provided |

| Digital Ammeter & Voltmeter | Provided | Provided |

| OCV Test | Provided | Provided |