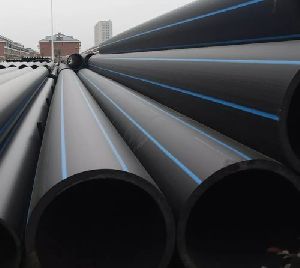

We are chiefly engaged in the manufacturing and supplying of HDPE Pipes all across the country. The HDPE Pipes or High Density Polyethylene Pipes are provided by us in all standard specifications. These HDPE Pipes have excellent chemical resistance and thus can withstand various acids, alkalis, slurries and almost any solution from pH 0 to 14. Therefore, these HDPE Pipes can be used instead of glass, lead, copper, rubber, stainless steel, etc. Specifications Of HDPE Pipes : Sizes : From 16 to 160 mm outside diameter Standard lengths : Of 50, 100, and 200 and up to 500 meter coils, or 6 & 12 meter straight pipes, as per pipe dimensions & customer specifications All dimensions are within the IS : 4984 - 1987/1995 tolerance Key Benefits Of HDPE Pipes : Withstand pressure up to 15Kg/cm 2 Can be butt welded at site in minutes making joints very strong Non-toxic and physiologically harmless and safe for portable water supplies Flexible, therefore, absorbs stress unlike rigid PVC Unbreakable and undeniable Light in weight-specific gravity : 0.955 Sizes up to 75mm or 2.5" can be supplied in coils of 50 or 100 meters, thus eliminating joints Completely inert, unaffected by acids, alkalis or any solutions from pH 0 to 14 Contains 2.3% carbon, the optimum for UV protection Withstand temperature up to 45-50 0 C, in constant use Safe for lying under water, across river or lake, in coastal salty marshes and other corrosive soils Up to 50 years durability Economical for transporting corrosive chemicals and fluids within the plant Ultra smooth interior / very low friction ARVIND & JAWAN HDPE Pipes Applications : Fuel gas Tube wells Irrigation Sewage/drainage Chemical industry Drinking water supply