Listing ID #1324084

Company Information

Ask for more detail from the seller

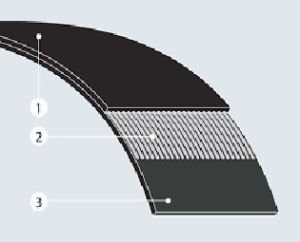

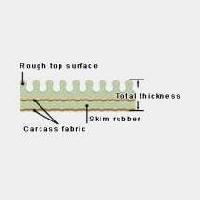

Contact SupplierConveyor belts generally consist of cover rubber, carcass and rubber skim coat. The reinforced breaker fabric is used for extra protection.

COVER RUBBER :

Covers of natural or synthetic rubber are designed to protect the carcass from -abrasion, impact, deterioration and other injurious influences. They are compounded to meet particular service conditions such as abrasion, oil, heat, fire, chemical resistant and antistatic, etc.

CARCASS :

Carcass of a belt maintains the belt tension and supplies structural strength; it does all of the work in supporting and pulling the load. Carcass consists of multiple plies of rubber impregnated fabric bonded with friction and skim coats. The fabrics most commonly used are; nylon, polyester and cotton.

RUBBER SKIM COAT :

An extra layer compound between plies that increases flex life and creates a more elastic link so that plies flex without separation. Skim coats cushion fabrics against impact and help protect against moisture.

BREAKER FABRIC :

A specially woven fabric between the cover and the carcass to improve adhesion and provide better resistance to cover stripping, gouging or tearing. This is normally used in belts handling primarily crushed and sized material which gives great impact to the belt when lumps drop at a loading point.

COMPOUND AND USAGE :

The cover rubber determines belt life and the selection of the correct cover rubber grade and thickness is most important.

HEAT RESISTANT CONVEYOR BELT :

In general, it is economical to adopt a heat resistant belt if the temperature of the material to be carried is over 60 C (140 F). As the damage of cover depends on the temperature and nature of transported material, the proper selection of a belt to fit particular operating conditions is important. Especially the relation of temperature between the material and belt surface should be considered when selecting the belt.

When transporting material of high temperature of belt surface rises by contact with the material, but on the return journey the heated surface gets cooled naturally by air so that the surface temperature becomes considerably cooler than that of the material. The temperature depends on kind, size, temperature quantity of material to be carried, belt speed, belt length and etc. This belt is designed for transporting cement clinker, cokes, sintered ores, soda ash, chemicals, fertilizer and etc.

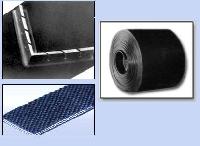

ABRASION RESISTANT CONVEYOR BELT :

Material being carried as well as idlers and frame of the conveyor may cause excessive wearing on normal belts. To prolong the life of the belts running under severe wearing conditions, special and super abrasion rubber is compounded for the belt covers.

OIL RESISTANT CONVEYOR BELT :

Oily material causes the ordinary rubber covers of the belt to swell and peel off, which results in a complete breakdown in the conveyor system. This belt compounded of oil-resistant -quality synthetic rubber has good resistance to the damaging effects encountered when conveying oil or oily materials.

FIRE RESISTANT CONVEYOR BELT :

This belt is a prerequisite to prevent fire risks in coal mines where not easily accessible and to reduce maintenance of the conveyors which may be damaged by flame at the blast furnaces of iron works.

ANTI-STATIC CONVEYOR BELT :

This belt is made especially for use where, for instance in the paper or textile mills, the products being carried stick to the belt surface, or fire risks may be involved due to electro-static sparks.

| Item | Grade | NN100 | NN120 | NN150 | NN200 | NN250 | NN300 |

|---|---|---|---|---|---|---|---|

| Min. Tensile Strength | Kg/cm-ply | 100 | 120 | 150 | 200 | 250 | 300 |

| Min. Tensile Strength | 1b/in ply | 560 | 672 | 840 | 1,120 | 1400 | 1,680 |

| Working Tension Rating | Kg/cm-ply | 8.4 | 10.0 | 12.5 | 16.7 | 20.8 | 25.0 |

| Working Tension Rating | 1b/in ply | 46.7 | 56.0 | 70.0 | 93.3 | 116.7 | 140.0 |

| Item | Grade | EP100 | EP125 | EP150 | EP160 | EP200 | EP250 |

|---|---|---|---|---|---|---|---|

| Min. Tensile Strength | Kg/cm-ply | 100 | 120 | 150 | 160 | 200 | 250 |

| Min. Tensile Strength | 1b/in ply | 560 | 700 | 840 | 896 | 1,1200 | 1,400 |

| Working Tension Rating | Kg/cm-ply | 10.0 | 12.5 | 15.0 | 16.0 | 20.0 | 25.0 |

| Working Tension Rating | 1b/in ply | 56.0 | 70.0 | 84.0 | 89.6 | 112.0 | 140.0 |