Listing ID #1962

Company Information

Ask for more detail from the seller

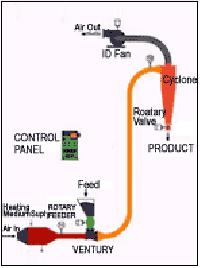

Contact SupplierOPERATION FLUID BED DRYER is designed to introduce the hot air stream at the base of the product container which is filled with the material. Induced draught is created by means of blower and fresh air is sucked in to the unit. The fresh air is heat by means of electrical heaters or steam or thermic fluid heaters. This hot air stream expands the bed of material at certain velocity & reating turbulance in the product. The phenomenon is known as fluidisation and offer conditions which are almost ideal for drying. Fluidisation produces full agitation of solid particles and since each particle gets surrounded by hot air, heat transfer is extremely high and uniform. The product is dried fast without appreciable loss of heat. Filter bags prevent particles escaping from the dryer.SUITABILITYThe conventional drying method of drying products in tray dryer is rather inadequate and trouble some. They occupy large floor space, have very high drying times, are labour intensive and offer uneven drying. On contrast Fluid Bed Dryer occupy comparatively lesser floor space, are very easy to operate & can dry material in least time as compared to tray dryer.In Fluid Bed Dryer, temperature distribution through out the product is uniform and the heat transfer rate is very high. Due to the reduce drying time high production rates are achieved. As the product is in close contact with drying air at low temperature and also for short duration, the physical and chemical properties of the products are generally not effected and therefore the dryer can effectively be used for heat sensitive products. Due to the continuous movements of product during drying lump formation, case hardening etc. are minimized. The Fluid Bed Dryer are most suitable for drying granular, crystalline, coarse or similar material in pharmaceuticals, fine chemicals, dyes, food and allied products. The Fluid Bed Dryer is not suitable for drying liquids or pasty materials.FLUID BED DRYERElectrically / Steam & Thermic Fluid Heated in which general structure, made out of mild steel & coloured in Standard Model & made out of S.S.304 quality material & polished to the matt finished in GMP Model, but contact parts i.e. Product Container and Retarding Chamber, are made out of S.S.304 / S.S. 316 quality material, with Non-Flameproof blower motor, ( Flameproof motor provided on demand ) suitable to dry wet material.The capacity ranging from 10 / 30 / 60 / 120 / 150 / 200 / 250 Kgs., with Steam heating / electrical heating & thermal Heating facility. SPECIAL FEATURESUniformity in drying and reduction in drying time. Atmospheric inlet air is filtered by means of non woowen filter cloth. PRE /MICRO V & HEPA filters can be provided on demand on extra cost to prevent any fine dust to pass through the products. Digital temperature indicator cum controller for inlet air & Digital temperature indicator for outlet air, are provided for electrically heated model. Digital temperature indicator are provided for inlet & outlet air, in steam / thermic fluid heated model. ( Temperature controlling valves will be in customer scope of supply ) Manually operated air dampers provided to control the inlet and outlet air flow. An explosion safety flap of adequate capacity at the rear of dryer and an earthing point to prevent static charge in the machine. Contact parts RETARDING CHAMBER & PRODUCT CONTAINER are made out of SS304 & polished to the mirror finished and other parts are made out of SS 304 and polished to the matt finished in Gmp model & made out of m.s. & coloured in standard model. OPTIONAL ( PROVIDED ON DEMAND ON EXTRA COST ) PRE /MICRO V & HEPA filters can be provided on demand on extra cost to prevent any fine dust to pass through the products. Pneumatic system for Lifting of product container & finger bag shaking with butter fly valve. Flameproof motor with weather proof / flameproof enclosure for operating panel.(It is recommended in steam heated model only. Power panel should be mounted out side the flameproof area.) Safe earthing arrangement with low voltage relay. Solid flow sensor monitor for monitoring the leakage in the air discharge filters. Differential pressure gauges across the air discharge bag and air inlet Hepa Filters. "PLC" based power panel with "MMI" based operating panel for process automation. Extra product container with trolley for more utilization of machine. Online sampling port at product container for sampling of material without shut-off the machine. Food grade silicon gasket set. Facility of mounting of blower with motor & heating chamber with air filteration unit out side the granulation room. Steam radiator made out of m.s. SS304 / SS316 on demand. Contact parts made out of SS 316 or SS316 L instead of SS304. Pneumatically operated inlet and outlet dampers. Silencer to reduce the noise level of exhaust air. A.C. Frequency drive for blower motor. Lifting and Tipling Device for Fluid Bed Dryers Container OPERATIONThis equipment is most useful to transfer the material from container of FLUID BED DRYER to INTERMEDIATE PRODUCT CONTAINER. With help of this equipment dust free and very speedy material transfer from FBD bowl is possible. The equipment is equipped with one cone type container which is provided with clamping hooks to clamp the FBD bowl, rubber gasket for air tight fitting between FBD bowl and cone type container. The container is also have a butterfly valve at bottom to drain the material in required IPC or any other container. The hydraulic system (power pack unit with cylinder) is provided to lift the complete assembly with FBD bowl and tilt the pair of cone type container and FBD bowl at 180 degree. With help of the hooks first clamp the FBD bowl with cone type container. Lift the whole assembly with FBD bowl at a desirable height. With help of hydro-mechanical system tilt the whole assembly at 180 degree. Finally all the material which was in the FBD bowl is transfer in cone container. Discharge the material in IPC or any other hopper, with help of butterfly valve which is provided at discharge of cone type container.SPECIAL FEATURESGMP point of view machine provided with S.S. cladding base, S.S. belt guards, S.S.cover on motor. No exposed painted surface on top of the machine. Hydraulic power pack is also covered with SS304 cover. Very less material transfer time making the next operation earlier & save time and dust free system save environment of working area. The system can be operate by single operator. Contact parts SS304 provided as a standard. SS 316 can be provided as a optional facility.