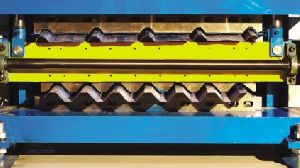

The spare parameters of the double layer wall tiles and roofing sheets making machine 1.manual decoiler and hydraulic fully automatic style is optional usage:it is used to support the steel coil and uncoil it in a turnable way. 2.coil feeding part usage:put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. 3.main roll forming machine part usage: in order to keep the product shape and precision, adopts welded sheet structure, motor reducer drive, chain transmission, roller was chromed which can keep the molding plate surface smooth and not easy to be marked when it is working 4. Automatic cuttting system 1).material: blade, puncher and mold material: cr12 steel with quenched treated 60-62 2).cutting system: advanced hydraulic drive, automatic cutting after forming, no distorting or wasting, high level safety factor 5.computer controlling part 1).plc brand: normally, it is delta. Mistubishi, panasonic, siemens are optional. 2).working model: fully automatic and manaul 3).working language: normally are english, chinese, russia. Can be set as per your requirements. 6. Hydraulic station 1).including one motor, one oil tank, one magnetic valve, one pressure gage, hydraulic oil tube 2).3kw, 4kw, 5.5kw, will be adopted as per your profile sheet.