- MOQ 1 Set(s)

- Shelf time1 year

- Machine materialsstainless steel

- Cooling rate1~50, can be set arbitrarily

- Work temperature+120~-190℃

- Number Of Flowercabinet freezer

- The frozen capacity250kg/hour

- The outside box size1300mm*1680mm*2160mm

- handcart size800mm*670mm*1760mm

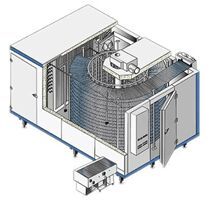

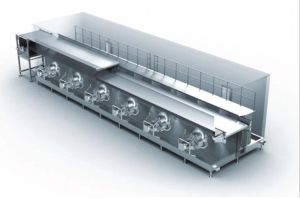

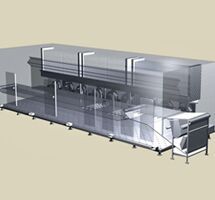

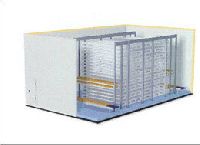

We offer Potato Iqf Freezing Tunnels Liquid Nitrogen Freezer. 1.Product discription: a.Place of Origin: Beijing China b.Brand Name: Cryogenic c.Model Number: SD-G-250H d.Freezing Medium: Liquid nitrogen refrigeration f. 250 kg per hour nitrogen equipment 2. Technical parameters: a. 250 kg per hour nitrogen equipment working temperature--- +120~ -190°c, can be set as you like b.Cooling rate---1~50°cmin, can be set c.The frozen capacity---250kghour 3.Product Advantage: a.The 250 kg per hour nitrogen equipment is use liquid nitrogen refrigeration. b.The lowest temperature: -190°C. c.The freezing rate is very big. d.The operation is simple, unmanned operation. e.The 250 kg per hour nitrogen equipment don't affect weight, taste, color, taste and cooking time. f. It need little space. g.The equipment investment is lower. 4.Application: The 250 kg per hour nitrogen equipment use for freezing vegetables( A variety of vegetables green peas, beans, corn, green beans, fried or boiled potatoes, carrots or pieces, whole or sliced mushrooms, cauliflower, peppers, tomatoes, cabbage and cut into pieces, sheets, strip . ), fruits ( Apple slices, pineapple slices, strawberries, blackberries, cherries, Marin fruit, plums, apricots, discuss, purple berries, grapes)and meats( Diced, fried meatballs, fish fillets, fish sticks, shrimp, shrimp) 5.Why the liquid nitrogen refrigeration is better than ammonia or Freon? a.The freezing rate is calculated by minutes and seconds�Liquid nitrogen is an ultra low temperature refrigerant in the Earth. b.Rapid cooling method to produce small ice crystals, reduce the damage of the product cell structure, thereby improving the quality of the product. c.Improve product becomes a rate �to reduce food dehydration and weight loss, improved frozen food texture, color and flavor.