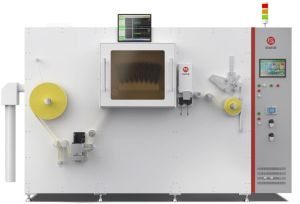

The single work station electrostatic perforat ing machine is a professional paper static hole punching machine for domestic foreign paper production manufacturers and production industries, with independent intellectual property rights. Compared with the laser hole punching machine, static hole punching can maintain stability while achieving high breathability avoiding the risk of glue leakage caused by excessive hole diameter during laser hole punching. Whether it is low breathability or high breathability requirements, static hole punching can meet them accurately. the same time, the production cost of the product is only 30% of that of laser hole punching. Core advantages: revolutionary breakthrough in static hole punching technology. The single workstation electrostatic perforating machine, with its "unique design concept advanced technical features" at the core, has shown superior punching and higher production efficiency in actual applications. Whether it is to improve product quality, control production costs, or optimize production processes, it can create significant value for enterprises and has won high from industry customers at home and abroad. Choose the single-station electrostatic punching machine to make efficient, accurate, and energy-saving punching technology your core competitiveness! (Note If you need to know the detailed parameters of the equipment or a customized plan, please feel free to contact us to get a dedicated solution. Please contact Business Manager or click the company's official website