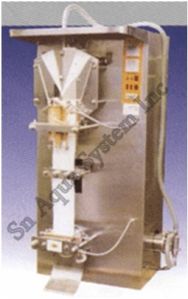

It is an automatically finish the processes of pouch forming, capping, filling, dosing, sealing, cutting and date printing, ect. This machine adopts pneumatic transmission, plc control, touch screen interface, and all components are stainless steel, and reliable and simple easy adjustment. Using advanced flow metering, and high measuring accuracy, packing capacity can be adjusted within the range 5-12.5 l. it adopts photoelectric calibration device, can ensure a complete and beautiful design, packaging materials by ultraviolet radiation to sterilize them, such as matching hundred clean air purification device can be realized in a state of complete high clean the entire process of packaging, the device is the ideal equipment for large capacity with mouth to achieve the automatic packaging . Main application: it is suitable for dairy products, soy milk, drinking water, liquor and other non-carbonated beverages; soy sauce, vinegar, rice , soups, sauces, sweet bean paste, bean paste, tomato sauce, mayonnaise, jam, hot pot material, chili sauce and other condiments; cream, condensed milk, palm oil, salad oil, animal oil and fat products; detergent, softener, bleach daily chemical products and fertilizer, additives, eggs and all kinds of liquid or semi-liquid chemical products’ packing.