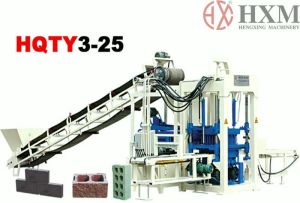

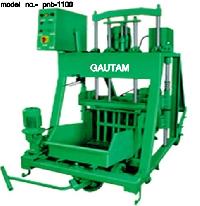

We are offering brick making mahine main technical specification production 4pcs/mould, 4, 000pcs/8 hours(hollow block:400x200x200mm) 24pcs/mould, 24, 000pcs/8 hours(solid block:240x115x53mm) 12pcs/mould, 12, 000pcs/8 hours(interlock:240x130x60mm) 20pcs/mould, 20, 000pcs/8 hours(paver block:200x100x60mm) working cycle time 15-20s main machine dimension 4000x3500x2500mm main machine weight 5.5t main machine power 25.7kw vibration force 40kn pallet size 850x550x25mm factory area 500 square meters the feature of technology 1, table vibration plus head press vibration system: a: table vibration plus head press vibration b: working stable and safely c: head press has three oil cylinders d: improve the block of density and intensity 2, control system: a. Mitsubishi plc, self diagnosed for trouble shooting b. Touch screen controller (eview, shenzhen), easy operation c. International electrical components: omron, schneider 3, proportional electro-hydraulic relief valves (taiwan, calyca) a. Its working steady with low noise b. Hi-precision c. Easy micro-adjusting d. Automatically control the oil pressure and oil flow d. American and british combination of sealing system it is connected 100% closely, no leaking at all, to make sure the hydraulic system working stable and smooth 4, 360 degrees of seconds’ pendulum feeding system: a, feeding motor is working with two or four transmission shafts b, it can feed various materials to the various moulds c, improve the block of density and intensity d, improve the feeding speed within 2 seconds e, it is very easy to clean the feeder. 5, heat treatment for the mould a, use the 16# manganese steel, b, heat treatment can reach hrc 61 c, working 150, 000times 6, pallets feeder of pusher brake system a, big size pusher brake for the different type of pallets b, feeding the pallets smooth, no stop 7, water cooling system a, keep the hydraulic oil of working temperature b, protect the hydraulic system and mechanical system