Our Products

Our offered Product range includes Paper Handkerchief Machine, Labor Protection Gloves Dipping Machines, Latex Toy Balloon Production Line, Multifunctional Small Special Shapes Latex Products Dipping Machine and Latex Party Balloon Machine Dipping Machine.

feature and functionrn1.put a roll in the form of flat belt push, equipped with stepless speed regulating device, rolling tension can be adjusted.2.embossed steel roller on wool roller (according to customer requirements using other material embossing roll).3.folding adopt vacuum adsorption form.4.each part adopt synchronous belt.5. Can produce different specifications of the models according to the requirement, can increase 1-4 color flexo printing device.technical parameters

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package

Delivery Time : 60 days after payment.

introduction

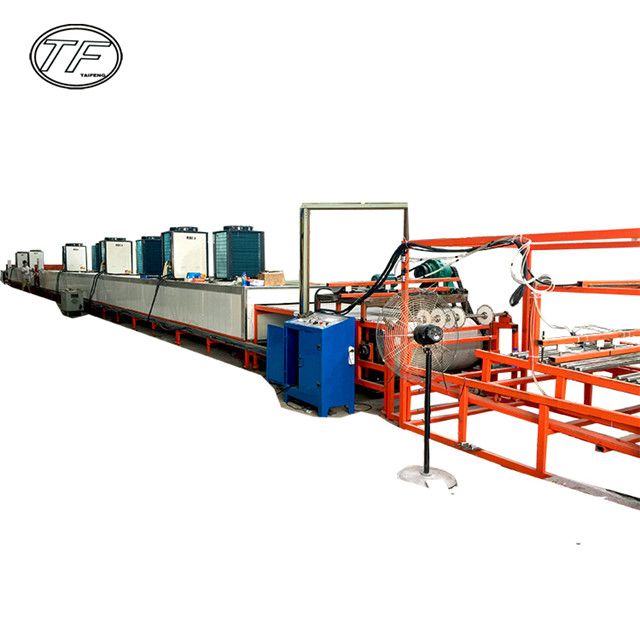

tf-bjx labor protection gloves dipping machines 1, machine according to various materials (natural rubber, butyronitrile, pvc) pu curing process of humanized design, reasonable process, automatic balance fill glue system, make products to be stable, uniform coating thickness, length, no hanging point, temperature uniformity, high output, easy to demould, etc.

2, oven using hot air circulation principle, the internal temperature of the oven, with high performance of insulation materials, ensure the temperature loss effectively, thus improve the thermal efficiency of the machine, the machine automatic temperature control system is adopted for the heating system, with high performance control switch, improve the accuracy of temperature control, so as to improve the product percent of pass.

3, special design of the elasticity of the piston mold connection device, mould replacement is simple, no off mold phenomenon.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

introduction

1.natural latex toy balloon production line adopts continuous production method and direct leaching method, uniform film-forming, beautiful in color, a variety of specifications and different ball can be producted at the same time, also can produce a variety of specifications color balloon; production line length have 35 meters, 60 meters, 80 meters and so on a variety of specifications, can automatic demoulding, high output, the product without the hanging point.

2.the machine is designed with more humanity according to natural latex curing forming process. It has reasonable process, latex self-balancing system, so that the quality of the gloves can be stable, the thickness and the length of the balloons can be uniform, no hanging points, heated evenly, high output, stripping balloons easy and simple.

3.the oven adopts the hot air circulation principle so that the internal temperature of the oven is even, uses fiber asbestos insulation materials to ensure the temperature does not drain, thereby improving the use of the thermal efficiency of the machine. The heating system of the machine uses pid temperature intelligent instrumentation, with high-performance control switch, improves the accuracy of temperature control, thereby enhancing the pass rate of the balloons.

4.specially designed mold with flexible piston connecting device, make the mold replacement is simple to operate, no balloons drop off happens.

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.

1.The natural latex product line adopts the plate type direct immersion way, the film formation is uniform, the color is bright, the production line length is 25 meters, may produce the balloon, the finger cover, the air bag, the condom and many kinds of unusual latex products and so on.

2.The machine carries on the humanized design according to the natural latex solidification molding craft, has the flow reasonable, the automatic balance restores the glue system, causes the product to be stable, the coating thickness and thin length is uniform, has no droop point, the temperature is uniform, Production output can be customized according to customer requirements, easy and simple demoulding and other characteristics.

3.The oven adopts the principle of hot air circulation, which makes the oven temperature even and chemical fiber asbestos insulation material, which effectively ensures that the temperature will not be lost, thus improving the use of the heat efficiency of the machine. The machine heating system adopts PID temperature intelligent instrument. With high-performance control switch, improve the accuracy of temperature control, thereby improving the product's qualified rate.

4, specially designed elastic piston type die connection device, the replacement die operation is simple, no drop die phenomenon appears;

Additional Information:

Payment Terms : T/T

Packaging Details : In seaworthy package.

Delivery Time : 60 days after payment.