Welcome to Zibo SK Refractory Co Ltd

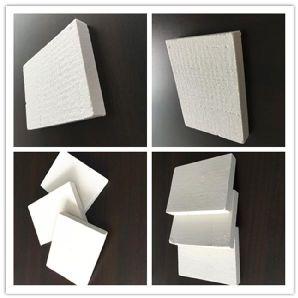

Manufacturer / Exporter / Supplier Of Ceramic Fiber Blanket, Ceramic Fiber Board, Ceramic Fiber Paper, Ceramic Fiber Textiles, Refractory Mortars, CERAMIC BULK FIBER, Insulating Fire Brick

Welcome to Zibo SK Refractory Co Ltd

Manufacturer / Exporter / Supplier Of Ceramic Fiber Blanket, Ceramic Fiber Board, Ceramic Fiber Paper, Ceramic Fiber Textiles, Refractory Mortars, CERAMIC BULK FIBER, Insulating Fire Brick

Ceramic fiber textiles contain the rope, tape, yarn and cloth. ZIBO SK ceramic fiber textiles are woven or braided from yarn consisting of refractory ceramic fiber with approximately 20% organic fiber. Inserted materials are reinforced into the yarn to increase the tensile strength of fibers. Stainless steel inserts are available for obtaining maximum strength at high temperatures. Glass filament inserts are used in applications where electrical resistance is required, ZIBO SK ceramic fiber textiles have been a workable insulation materials for thermal gaskets and wrapping, its unique functions and features are gaining more popularity in the high temperature insulations. Features Low thermal conductivity Low heat storage Reduces fume emission around refractory Excellent thermal shock resistance Resistance to gas velocity Easy to install Adheres to most ceramic and metallic surface Excellent corrosion resistance Insert to most chemicals Impermeable to molten aluminum, zinc, copper & lead Asbestos free Categories of Textiles Yarn, cloth, square braided rope Round braided rope, twisted rope, tape, sleeve Typical Applications Gasket and wrapping material Cable and wire insulation Welding curtains and blankets Furnace curtains & heat zone separators Fuel line insulation Expansion joints High temperature seals and packing in furnaces Door seals for stove and oven Thermally insulating pipe wrap Kiln car seals

ZIBO SK refractory mortar is a new kind of paste-like bonding material which is formed particularly from specially sorted powder made from the identical raw materials and classification temperatures in light with the brick utilized in furnace and their refractory grades. During the process of production, it undergoes chemical reaction and stirring-up with added inorganic bonding agent and additives. ZIBO SK refractory mortar can be classified into four categories according to its service temperature in normal circumstances and they must be used to support the lightweight mullite brick subject to the same class. Category Air setting refractory mortar Grade-23 Grade-26 Thermal�¢ï¿½ï¿½hardness refractory mortar Grade-28 Grade-30 Features High bonding performance for bricks engineering Excellent sealing capability, resistance to erosion High refractoriness under load Outstanding efficiency in reducing the slag Ensure well-sealed joints for convenient installation Consistency and bonding effectiveness Typical Applications Necessary auxiliary materials for insulating Firebricks in the furnace lining

Share your thoughts with other customers for Zibo SK Refractory Co Ltd

Add Review