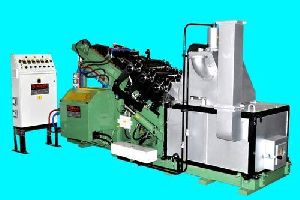

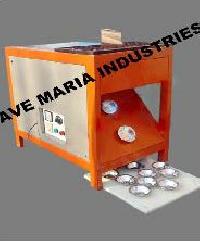

Welcome to Devaki Engineering Enterprises Private Limited

Welcome to the most renowned and trusted equipment manufacturer for lead acid battery industry in india. The company have been supplying quality Battery Making Equipment to Battery industry for the last 3 decades. Its in-house cad-aided design facility, state of the art manufacturing center, dedicated & experienced engineers have attributed to our leadership in Battery equipments for all these years. Continued innovations & adapting modern technologies to improve the efficiency& reliability of the machines have helped our customers to improve their operations& profitability. Our focus has been always our customer satisfaction, offering value products with operator friendly, easy to maintain, easy to operate features. Many of our Equipments have also been exported to various countries.