Welcome to Dev- Dhan Enterprises

supply of biomass briquette

-

CEO

Naresh Mahajan

-

Year of Establishment

2000

-

Primary Business

Retailer

-

Number of Employees

51 - 100

-

Annual Turnover

Rs. 0.5 to 2.5 Crore Approx.

Welcome to Dev- Dhan Enterprises

supply of biomass briquette

CEO

Naresh Mahajan

Year of Establishment

2000

Primary Business

Retailer

Number of Employees

51 - 100

Annual Turnover

Rs. 0.5 to 2.5 Crore Approx.

We offer highly efficient Hot Water Generator that is designed and manufactured to meet the industrial requirements. Our industrial hot water generator is extremely user friendly in nature, thus very easy to handle and operate. It is widely demanded in the market for its safety measures, noiseless operation, and high efficiency. We provide industrial hot water generator at very moderate prices to suit the budget of all. Attributes Fully automatic Easy operation & Fail proof system Packaged models Record efficiency Useful for sensitive temperature controls in driers Technical Features Available from 50, 000 Kcals / hr to 20, 00, 000 Kcals / hr Maximum temperature of operation - 140°C Exempted from I-B-R

The Thermic Fluid Heater that we offer our clients is sourced from trusted vendors. Our fuel fired thermic fluid heater is easy and safe to handle, as it is incorporated with various safety measure equipment. They need low maintenance and provide long lasting brilliant performance even in tough weather conditions. Salient Features Fully automatic Easy operation & fail proof system Outside the purview of IBR 100% depreciation in the first year High efficiency Technical Specifications Capacities from 50, 000 Kcals/hr to 10, 00, 000 Kcals/hr Maximum operating temperature of 300 o C Over all efficiency of 88%± 1% on N.C.V Four heat transfers Efficient combustion, forced circulation, liberal heat transfer areas & large furnace volume Specifications Details Unit NT-50 NT-100 NT-200 NT-300 NT-400 NT-600 NT-1000 Operating Parameters Capacity KCals/Hr. 50000 100000 200000 300000 400000 600000 1000000 Max. Operating Temp. (At the outlet of the unit) 0 C 300 300 300 300 300 300 300 Fuel Oil Consumption At full load LDO FO Kgs/Hr Kgs/Hr. 5.4 10.8 21.5 22.6 32.4 33.9 42.9 45 64.3 67.5 107.2 112.5 Efficiency (GCV) % 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 86+/-1 Burner Contro -------------------------ON-OFF------------------ Electric Supply AC-3 Phase - 415V +/- 6% 50 Hz 4 Wire Thermic Fluid Pump Motor (HP) 3 5 7.5 10 10 20 25 Blower Motor (HP) 1 1.5 2 2 3 5 10 Fuel Oil Preheater (For F.O. Fired Unit Only) KW - - 3 4.5 4.5 6 9 Total Elec. Load For LDO Fired Units For FO Fired Units HP HP + KW 4 6.5 9.5 9.5+3 12 12+4.5 13 13+4.5 25 25+6 35 35+9 Length (Mts) 2 3 4 4 4 4 4 Width (Mts) 2 3 4 4 4 5 5 Clear Height (Mts) 2.5 2.5 4 5 5 5 6 Fuel Gas Outlet (MM) 250 250 250 300 30 400 500 Cross Dry Weight (Kgs) 1000 1350 1750 2400 2900 3500 5250 PARAMETERS UNIT NTC : 200 NTC : 300 NTC : 400 NTC : 600 NTC : 1000 - - Heat Output Kcal/hr 2, 00, 000 3, 00, 000 4, 00, 000 6, 00, 000 10, 00, 000 - - Outlet temperature (max) 0 C 300 300 300 300 300 - - Temp rise ( T) in the heater 0 C 25 25 25 25 25 - - Pressure at heater outlet Kg/cm2 2.2 2.2 2.5 2.5 2.5 - - Flue gas duct diameter mm 250 300 300 350 450 - - Inlet / Outlet connection of heater mm 50 50 65 65 100 - - FUEL CONSUMPTION Coal Kgs/hr 64 96 128 192 320 - - Wood Kgs/hr 87 130 174 260 435 - - ELECTRICAL LOAD Thermic Fluid Pump Motor Kw 5.5 5.5 7.5 11.0 15 - - I.D. fan motor + F.D. fan motor Kw 1.5+0.375 2.2+0.75 2.2+0.75 3.7+1.5 5+2.2 - - Total Connected Load Kw 7.375 8.45 10.45 16.2 22.2 - - Designs and Specifications subject to changes due to constant research and development The efficiency is guaranteed on the test bay with commercially clean internal and external heat transfer surfaces

We provide our customers the Coconut Shells of premium quality that deepens their trust in our services. These Shells are well packed to maintain their rich quality and provide our customers the best products. Features Good Packaging Quality material Free Delivery Used in Refractory Foundry

We deal in Biomass Briquette (White Coal) which is substitute to charcoal. Biomass based briquette is non-conventional source of energy and eco-friendly in nature. Our biomass-based briquette is manufactured using binder less technique, thus it is 100 % natural and free from any kind of chemical. White coal provided by us is renewable in nature, non-polluting and highly economical. Raw Material used Sugarcane Baggase Saw Dust Groundnut Shell Forest waste Charcoal etc. Characteristics Moisture : Less than 5% Sulpher : 0% Carbon : 60% Ash : 5 - 8% High specific density : 1200 Kg/m3 Bulk density : 800 Kg/m3 Features Eco friendly & Renewable Energy fuel Economical and cheaper than other solid fuels i.e., coal & wood Higher thermal calorific value around 4000-4250 Kcal/Kg No fly ash when burnt Consistent high burning efficiency due to low moisture Contain high density & Higher Fix Carbon value Easy for Transportation, feeding & combustion due to unique shape Combustion is more uniform compared to other coal Demand in market due to high-rise in fossil fuels price

We offer a large range of excellent quality Hot Air Generator that is procured from the well-reckoned vendors. Our direct-fired hot air generator is manufactured from the premium quality raw materials under high precision. It is fully automatic hot air generators in oil-fired design for drying applications. Salient Features Fully automatic Easy operation Packaged models Compact design Caters to hot air requirements of any drier Record efficiency Economically cheapest clean hot air available instantly Low motive power required Replaces electricity, Steam, thermic fluid , media to generate hot air Drying Time & drying cost considerably reduced Comprises Of Oil fired hot air generator model technology blocks comprise of an advanced shell in shell type radiant heat transfer section connected to a multiple pass shell & tube type convective heat exchanger. Ideally Suited To Totally new venture Bulk production of a single product Existing industries, which already have number of tray driers working Working industries having multiple product range for drying Internal Recirculation Type Technodry Block Model Operating Parameters TDB-35 TDB-50 TDB-100 Rating (K.Cals/hr.) 35000 50000 100000 Max. Outlet Temp. ( o C) 140 140 140 Air Output (m3/hr.) 2800 4000 8000 Type of Fuel LIGHT FUELS LIKE LDO/HSD/KEROSENE Fuel Oil Consumption (kgs/hr) 4.1 5.80 11.5 Burner Control ON/OFF Capacity in terms of Trolleys (Nos.) 4 6 10 Efficiency (%) 84 + 2% Electric Supply A.C.3 PHASE : 415V + 6% 50 HZ 4 WIRE Air Circulating Blower 3.0 5.0 7.5 Combn. Blower 1.0 1.0 1.5 Oil Pump 0.5 0.5 0.5 Total Electric Load 4.5 6.5 9.5 Flue Gas Outlet (mm) 150 150 200

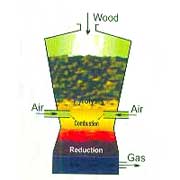

We provide our clients with good quality Biomass Gasifier . It undertakes the process of converting solid biomass fuel into combustible gas through thermo-chemical reactions. It is efficient for biomass gasification process and is highly reliable for their working. Use The gas produced is low heating value fuel; possessing calorific value of 1000-1200 Kcal/Nm3. 1 kg of air-dried biomass produces 2.5-3 Nm3 of gas through gasification. Gas Composition Carbon monoxide -20-22% Hydrogen (H2O)-15-20% Methane(CH4)-2-3% Carbon dioxide (CO2)-9-11% Nitrogen(N2)-45-54% Water vapor (H2O)-10-15% Heavy hydrocarbon-0.2-0.4% Â Used In Ovens Boilers Kilns Hot air generator Thermic fluid heaters for thermal applications Features Appropriate design Good conversion efficiency Better control on burning Production of clean flue gases in the exhaust Low investment Reduction in deforestation Reduction in Diesel/Kerosene/Furnace Oil/ LDO cost Capable of withstanding high temperatures up to 1860 degree centigrade Net zero CO2 emission

Share your thoughts with other customers for Dev- Dhan Enterprises

Add Review