Listing ID #5072668

Company Information

Ask for more detail from the seller

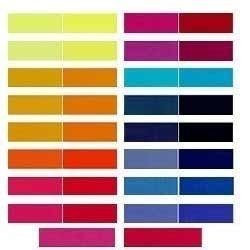

Contact SupplierThese dyes are called as 'HOT BRAND DYES’. These dyes are applied under strong alkaline condition at high temp. of application compared to cold brand dyes. These dyes contains very good fastness properties. These dyes are suitable particularly for Printing, Cotton, Viscose, Cuprarnmonium rayons & natural silk. Dyeing process of these dyes is as below:

Setthe dye bath at 50°C, add predissolved dyestuff, enter the material and run for 15 minutes. Add half of the predissotved Glauber's salt and continue dyeing. now gradually raise temp. to 80-85°C and in the mean time add remaining amount of predissolved salt and continue dyeing for 10 minutes further after maintaining temp. 80-85°C- now add soda ash solution and continue dyeing for 30-60 minutes maintaining temp, 80-85°C and wash the material,

| Depth of Shade % | Salt (gms/ lit.) | Soda Ash (gms/lit.) |

|---|---|---|

| Up to 0.5 | 30 | 10 |

| 0.5-1.0 | 45 | 15 |

| 1.0-2.0 | 60 | 15 |

| 2.0-4.0 | 70 | 20 |

| Above 4.0 | 90 | 20 |

(i) PAD-BATCH-PROCESS :

Dye Stuff + Caustic Soda 15 gmsilit. + Glauber's salt 10-30 gms/lit. —-> 24 Hrs Batch —-> Wash

(ii) PAD - DRY - BAKE PROCESS :

Dye stuff + Urea 200gms/lit. + Soda Ash 10-20 gms/lit —>Dry --> Bake 30 Sec. at 200°C OR (3 min. at 150°C) ---> Wash

(iii) PAD-DRY-STEAM PROCESS:

Dye stuff + Soda Ash 10gms/lit. + Resist salt 10gms/lit.-—> Dry --> Steam (7-10 min. at 100-105°C) —-> Wash.

(iv) PAD- DRY -PAD- STEAM PROCESS:

Dye stuff + Resist salt 10qmsilit. —=Dry—> Chemical Pad (Caustic Soda 10-15 gmsilit. + Salt 200-300 gmsfit.) —> Dry ---> Steam —> (7-10 min, at 100-105°C) —> Wash