Listing ID #4324222

Company Information

Ask for more detail from the seller

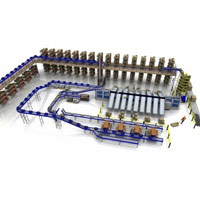

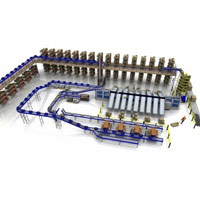

Contact SupplierInfeed Conveyor With Big Hopper (Model : EE-IC-Z)

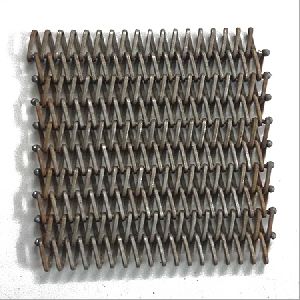

We are well recognized in successfully matching up with the demands of a wide variety of feeding systems. These comprise in-feed belt conveyors with feeder & big hopper which is used for feeding materials in upper hopper of filling machines and finds suitability in packing products like Pulses, Snacks, Seeds, Sugar, Rice, Tea, Namkeens, Granules Dry Fruits, Grains. These are made available in three conveyor options including In-feed belt conveyor (Model: EE-IC-Belt), In-feed bucket conveyor (Model: EE-IC-Bucket) and In-feed Z conveyor (Model: EE-IC-Z).