Listing ID #5361817

Company Information

Ask for more detail from the seller

Contact SupplierOrifice Plate Flowmeter

Series OP Orifice Plate Flowmeter

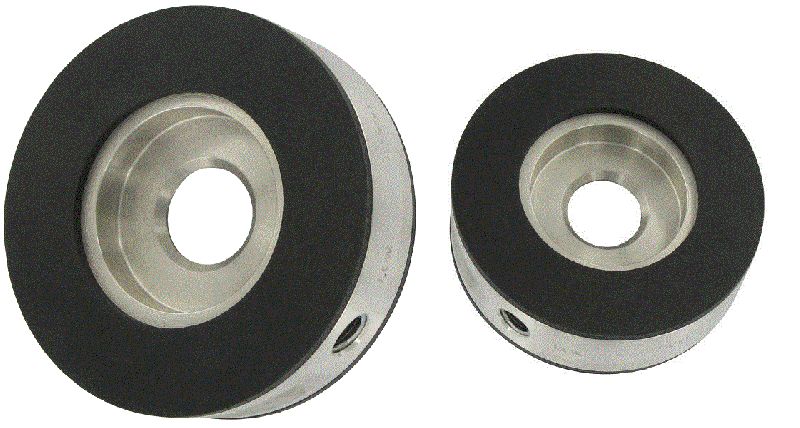

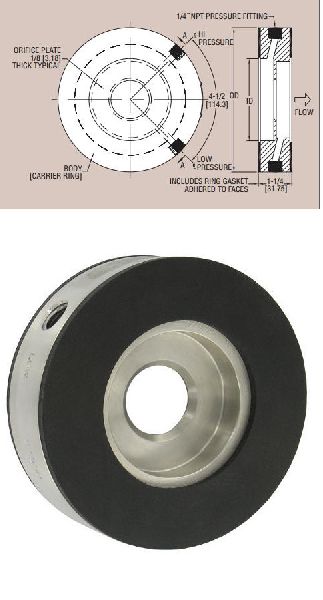

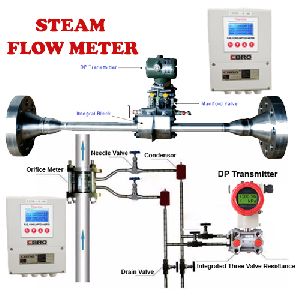

The Series OP Orifice Plate Flowmeter is a complete orifice plate flow metering package. It incorporates a stainless steel orifice plate with a unique holder or carrier ring containing metering taps and integral gaskets. It was designed for use wherever there is an application for a conventional flow orifice plate. It can also be used in place of other primary differential producers for efficiency and cost effectiveness. Installation is accomplished simply by slipping the unit between standard flanges (orifice flanges are not required). The Series OP is available in line sizes from 1/2" to 24" and can be used with compatible liquids and gases.

Features:

Applications:

Accuracy:

The Series OP utilizes the corner tap proportions as defined in ISO 5167. While this code may not be referred to as International Standard until accepted by the ISO Council, the ASME Fluid Meters Research Committee has suggested that the dimensionless coefficient equation developed by the International Standards Organization (ISO) and presented in ISO 5167 is significantly better for the broad spectrum of flow measurement applications throughout process industries.

The coefficient values used in the Series OP bore calculations represent the same confidence level assigned to the flange and radius taps widely accepted in fluid flow measurement.

The accuracy assigned to the coefficient values is ±0.6% full scale flow for d/D (Beta) values 0.2 to 0.6 and ±0.7% for Beta values 0.7 to 0.75 (i.e. ß of 0.7 would have an uncertainty value of ±0.7% full scale flow).

Accuracy of the differential signal produced by the Series OP equals or exceeds that of a properly manufactured and installed flange or radius tap orifice meter.

Mounting:

The orifice metering primary shall be suitable for installation between standard ANSI 125/150# flanges (any material) mounted on standard pipe (any material). The unit shall be "self centering" within the bolt circle of the flanges. No alignment of the orifice shall be necessary unless used with 300# or non-standard flange ratings. Drilling and or tapping of the main or flanges will not be allowed or required. The overall laying length shall be 1.25 ?? including pre-attached ring type 1/8 ?? thick Buna "N" Gaskets.

Pipe Requirements:

Upstream and downstream pipe requirements are contingent upon two factors: (a) Beta Ratio-ratio of the orifice bore to the pipe I.D. (d/D); (b) The type of fitting or disturbance upstream of the Series OP. For most applications, 10 pipe dia. upstream & 5 dia. downstream are sufficient. (5 pipe dia. up and 2 dia. down are acceptable for non-critical application.)