Listing ID #125569

Company Information

Ask for more detail from the seller

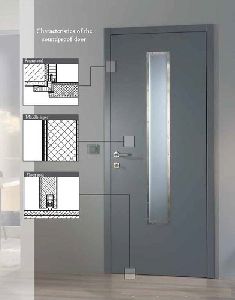

Contact SupplierWe bring forth high quality Sound Proof Enclosures that are highly acclaimed among the clients. Our Sound Proof and Environment Friendly Acoustic Enclosures, and Canopies from ERAM are developed with the aid of CAD software so that they can be tailor made as per the requirements of the clients. They have adequate ventilation and made of insulating materials that are fire radiant. The suitable thermal lagging helps in avoiding localized heating of adjoining part of exhaust. Besides, we are one of the reliable Generator Sound Proof Enclosures Manufacturers and Suppliers in India.We at EEPL manufacture an acoustic enclosure with our innovative techniques and keeping in view the

The acoustic enclosure is designed with the help of CAD software. The enclosure can be tailor made as per the requirement and depending upon the capacity of D.G. Set. The enclosure is ideal for all locations of installation.

Construction Details