Welcome to Exo Packaging

Manufacturer / Exporter / Supplier / Retailer Of Pet Preforms Moulds, Agitated Nutsche Filter, Wiped Film Evaporator, Pressure Leaf Filter, WIPED Thin FILM EVAPORATORS, AGITATED Pressure NUTSCHE FILTER /

Welcome to Exo Packaging

Manufacturer / Exporter / Supplier / Retailer Of Pet Preforms Moulds, Agitated Nutsche Filter, Wiped Film Evaporator, Pressure Leaf Filter, WIPED Thin FILM EVAPORATORS, AGITATED Pressure NUTSCHE FILTER /

Wiped Film Evaporator is designed to handle challenging evaporating requirements with materials that are heat-sensitive, highly viscous, or of low thermal conductivity. This technology involves separating volatile compounds by introducing a mechanical agitated thin film of feed material to a heated surface.

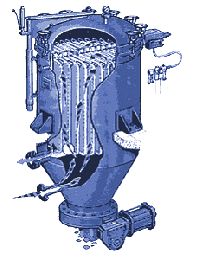

The Pressure Leaf Filter is a MSSS Vertical Vessel with Filter Leaves inside. The leaves are mounted vertically on a common manifold pipe, through which the filtered liquid flows out. On the top, the leaves are held by a vibrating shaft . A mechanical vibrator driven by electric motorpneumatic vibrator is provided for vibrating the leaf shaft for cake discharge. Jacket for hot filtration can be offered if desired Over flow, ventsteamair charging, pressure gauge & safety valve are provided on the top.

Agitated Nutsche Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated Nutsche Filters are extensively used in Chemical, Herbal, pharma, agro chemical and the food industry.

Agitated Nutsche Filter is a closed vessel designed to separate solid and liquid by filtration under pressure or vacuum. The closed system ensures odourless contamination free and non-polluting working conditions maintaining product purity and hygiene. Agitated Nutsche Filters are extensively used in Chemical, Herbal, pharma, agro chemical and the food industry.

Wiped Film Evaporator is designed to handle challenging evaporating requirements with materials that are heat-sensitive, highly viscous, or of low thermal conductivity. This technology involves separating volatile compounds by introducing a mechanical agitated thin film of feed material to a heated surface.

Share your thoughts with other customers for Exo Packaging

Add Review