Listing ID #1231185

Company Information

Ask for more detail from the seller

Contact SupplierFortune Engineers has reached the peak of success in Manufacturing and Supplying Semi Automatic Fly Ash Brick Plant. Semi Automatic FlyAsh Brick Plant that we offer in the market can manufacture bricks in different sizes as per the clients̢۪ requirements. The size of the brick can be changed by altering mould set in 1-2 hour. Keeping the current market scenario in view; we have fixed reasonable prices for our Semi Automatic Fly Ash Brick Plant.

| |

|

Productivity

| Model | |||||||

| Brick Size | 230x150x90 mm | 230x110x75 mm | 190x90x90 mm | 230x150x90 mm | 230x110x75 mm | 190x90x90 mm | |

| No of Bricks per stroke | 8 | 10 | 12 | 8 | 10 | 12 | |

| Stroke cycle | 20 Sec | 20 Sec | 20 Sec | 15 Sec | 15 Sec | 15 Sec | |

| No of Bricks/Hr | 1440 | 1800 | 2160 | 1920 | 2400 | 2880 | |

| Achievable capacity Bricks/Hr | 1008 | 1260 | 1512 | 1344 | 1680 | 2016 | |

| Production in 8 hour shift | 8064 | 10080 | 12096 | 10752 | 13440 | 16128 | |

Production Process

| Raw Material feeding | Manual feeding/Volumetric Control |

| Mixing | Batch type intensive rapid mixing with manual water feeding. |

| Brick Production | Powder compacting technology with PLC controlled system to give sufficient pressure for inter-molecules bonding |

| Green Production Handling | Manually on Pallets |

| Green Product Curing | Manual Curing System By Sprinkling Water jets |

Bricks Specifications

| Particulars | Value | Unit | Remarks |

| Brick Weight | 2.7-3.2 | Kgs | Size 230x110x75 mm |

| 2.3-2.7 | Kgs | Size 190x90x90 mm | |

| Compressive Strength | 70-90 | Kgs/cm2 | Recipe is optimized to achieve it. |

| Water absorption | 15-20 | % | Depends on composition |

Composition

| Particulars | Range % |

| Fly Ash | 60-70 |

| Sand | 15-25 |

| Cemen | 5-10 |

| Lime | 10-12 |

| Zypsum | 2-5 |

| Stee Plant Slag | 10-30% |

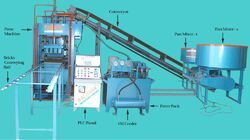

Scope of Supply for Semi Automatic Fly Ash Brick Plant

| Particulars | Purpose | ||

| FEMBP-02 | FEMBP-03 | ||

| Pan Mixer | Mixer with suitable regenerated Gearbox, having heavy duty Rollers. The entire inside body is provided with EN#9 liners | For perfect mixing of ingredients to give consistency in Product quality. | |

| Cap | 500 kgs | 750 kgs | - |

| Motor | 15HP Crompton/ Kirloskar/Std | 15 HP Crompton / Kirloskar/Std | - |

| Belt Conveyor System | 5 meter long Conveyor system with structure and 1 HP Electric Motor & Gearbox bottom Guide Support base, top discharge chute. | - | For holding & conveying mix material to Press Feeding Hopper, by the time the next batch gets ready in Pan Mixer. |

| Feeding Hopper | 500 Kgs | 750 Kgs | Hold up of wet mix in storage hopper gives the minimum time required to initiate Cementing Process of Ingredients, before the mix is subjected to high hydraulic Pressure, & for continuity of the operation. |

| Hydraulic Brick Press | Manual Lever operated Hydraulic Brick Press of 50 Tons loading capacity. The structure of the Machine is fully window cut type. The Machine is provided with Hydraulic Cylinders for

The Machine is provided with Dust covers for punch mounting Plate, ejection Cylinder assembly & Feeder Trolley The Machine consists of Hydraulic Power pack with Dowty make gear Pump with 10 HP CG or Standard make Motor, Standard make Hydraulic components & Italian make lever operated Valves | Having 8/10 or 12 Bricks Cavities depending on selected Size. | |

| Loading Capacity | 50 T | 84 T | |

| Pressings Cyliners | 1 No | 2 No | |

| Ejection Cylinder | 2 Nos | 2 Nos | |

| FeederTrolley Cylinder | 1 No | 1 No | |

| Pallet Conveyor | 10 feet long conveyor for transporting pallets, till they are handedled | Ease of operation & time cushion for labour handling green product pallets. | |