Listing ID #1377963

Company Information

Ask for more detail from the seller

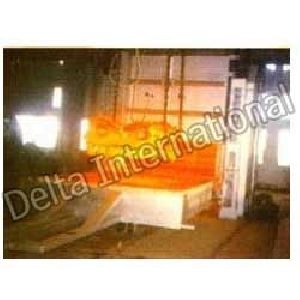

Contact SupplierWe are involved in constructing Bogie Hearth Furnace for any charge weights. The Operating temperatures of Bogie Hearth Furnace may vary from low temperature application with gas circulation to temperature above 1200°C. The heating of Bogie Hearth Furnace could entail gas or liquid fuel fired including high velocity burners and also electrically heated. The Bogie Hearth Furnace is used for the tempering of hardened alloy steel bars, coils and castings.

|

|

|

|

|