Listing ID #756312

Company Information

Ask for more detail from the seller

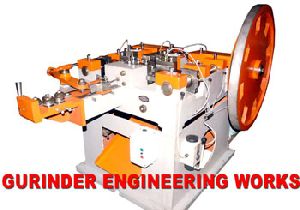

Contact SupplierWe offer high speed Wire Nail Making Machine that is appreciated for flawless performance, easy operation and sturdy construction. Our Wire Nail Making Machine is fully automatic wire feeding unit that carries out clamping of wire through conical rollers, heading operation, point forming and process of finished nails automatically. The technical specifications of our Wire Nail Making Machine vary with chosen model of the machine for wire diameter, length of nail and production. Solid main bed bushes increase the bearing surface and eliminate deformation with fluent lubricating oil film that ensures long life of bushes. The flywheel is mounted on a support independent from the main crank-shaft which therefore is not affected by stresses produced by freewheel itself and by the drive belts. Spiral type bevel gears run in continuous lubricating system and need no maintenance and are noiseless.

The round section hammer slide allows correct alignment with the connecting rod, a larger support surface and excellent lubrication. Moreover, an air circulation system cools the slide's running guide and keeps dirt away from the slide itself. The nails ejector is driven by a cam, so there is no contact between the punch and the ejector. The crank shaft and lateral shafts are of high quality steel fully ground and are counter-balanced to extend cutters life. Cutters and grippers are adjusted by means of vertically positioned screws operating on the wedges.

The grippers die box is made up of two slides; the stationary gripper is mounted on the former, the sliding one is mounted on the latter that offers large bearing surfaces. Grippers can be removed from the box without taking the box off from the press. This allows shortening the down-times. The wire feeding driven by rollswedge system is self-locking. The clamping pressure on the wire is adjustable, the wire release is pneumatic and the centralized lubrication is partially continuous & partially timer controlled. The oil gets accumulated in a tank located in the machine bed and it is filtered both on suction & in delivery machine and is totally covered which exceptionally reduces the noise level. Wire Nail Making Machine is equipped with 110 v auxiliary controls, a PLC (program logic control) controls the lubrication systems, the wrong wire feeding alarm and operator machine safety devices.