Listing ID #4017481

Company Information

Ask for more detail from the seller

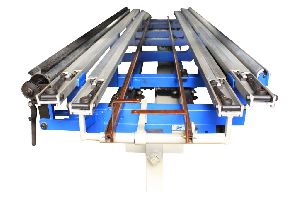

Contact SupplierHtex outlines are made according to your prerequisite in tallness and width going between 120 cms. (50″) up to 400 cms. (160″ ) With in this range each asked for width can be suited in phases of 25 cms. (10″). For twin pillars your decision are it is possible that one casing covering both the twist shaft width, or one single casing with twofold side bracing framework or two single casing with coupling gadget. Twofold width, divisible twist tying outline allow defended chipping away at looms with twin twists. The isolated tying edge can likewise be utilized for weaving machines ordinary single shafts.

Htex dressing outlines are made out of exceptionally expelled combination segments which are extremely strong and light weight and in the meantime tough for quite a long time of administration. The yarn clasp holding and tensioning gadget are streamlined for speedier dressing; it is intended for simple changes vertically and on a level plane, to alter the tallness as per your linger. They come in extensive variety of working width, as per your weaving machines decision.

For quicker dressing and simple clipping of coarser twists underneath 12’s we prescribe you our HD/UB sort outlines, gave exceptionally solid U sort rubber treated, composite clasps, with oval molded EN-9 steel bars. Bracing arrangement of Htex dressing outline is intended to press the whole twist sheet in parallel and firm condition. Rubbers on both the sides of strain rails ensures firm hold to the most tricky and fine twist. Htex additionally has Heavy Duty Bar Tensioning Yarn Dressing Frame exceptionally created for denim and coarser twists. These casings are exceptionally strong. Extraordinary sort outlines for any transported in machines can likewise be made on arrange.

For faster dressing and easy clamping of coarser warps below 12’s only. We recommend you our HD/UB-type rames, provided with very sturdy U-type, rubberised, alloy clapms, with oval shaped EN-9 Steel bars.