Listing ID #4966572

Company Information

Ask for more detail from the seller

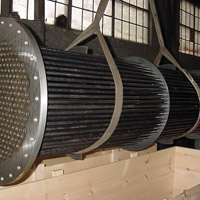

Contact SupplierHeat exchangers require approved welding procedures and our ASME certified welders combined with our design and project team are experienced to be able to meet the strict requirements of industrial heat exchangers. All designs meet the requirements of the ASME Code and TEMA, whether they are made from 4” diameter pipe or 120” plate shells. We also offer heat exchanger repair and maintenance.

Shell and Tube Heat Exchangers Fabrication and Service: Coolers, Heaters, Condensers, Vaporizers, Reboilers, Falling Film Evaporators, Air Cooled Heat Exchangers, Crystallizers, Industrial Heat Exchangers & Sanitary Heat Exchangers

Material of Construction:

Stainless Steel 304, 316 & Special material like Duplex, Super Duplex, Monel, Inconel, Brass, Clad (Explosion Bonded)

Type of Construction:

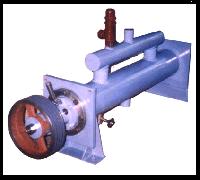

Straight Tube

· U – Tube type

· Fined Tube type

· Spiral Tube type

· Double Tube Sheet

· Clad Tube Sheet Type

· Rubber Lined

Design and Fabrication Services:

· Design and fabrication of Shell & tube type Heat Exchanger

· Replacement tube bundles, shells, channels, baffles, heads and other replacement parts for existing heat exchangers