Listing ID #4084809

Company Information

Ask for more detail from the seller

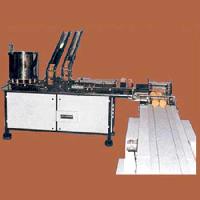

Contact SupplierHot filled bottles from the filler will be transferred into the Cooling Tunnel which will have three zone cooling system. Each zone will be maintained at a higher temperature than preceding zones, with the final zone having the lowest temperature which is close to the room temperature. To hold the temperature in first zone, there will be a steam injector system as well as fresh water delivery system. Both controlled by a digital temperature controller set on heat-cool principle. The function of this temperature controller will be if temperature is above a pre-set level, cold water will be taken in and temperature lowered.

The Spray system is made from stainless steel perforated sheets such that entire width and length is covered by water spray. To prevent water from collecting on the bottles an air knife is placed at the outfeed of the machine, which will blow away the excess water.From the Cooling Tunnel when fresh water is injected into the tank , there will be over flow of the hot water which gets collected in 1200 liter tank built into the tunnel and will be circulated by Plate Heat Exchanger and will bring down the temperature to 35 0 c. Tunnel will be connected through circulating pump like filling piping water system.We use MCC make plastic chain and matching sprocket in the cooling tunnel. The main body is made entirely from Stainless Steel.