Welcome to J. J. Precision

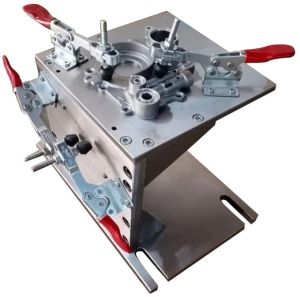

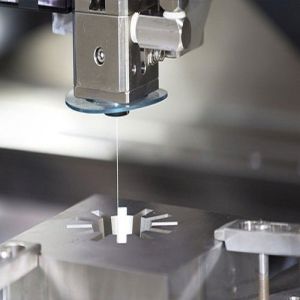

J. J. Precision, a distinguished name in the realm of precision engineering solutions. Founded in 2009 by Mr. Varghese John and headquartered in Pune, Maharashtra, we specialize in exporting, supplying, and providing comprehensive service offerings.. Read More

-

Founder

Mr. Varghese John

-

Year of Establishment

2009

-

Primary Business

Exporter

-

Number of Employees

6 - 20

-

Annual Turnover

Rs. 2.5 to 5 Crore Approx.