Listing ID #3893984

Company Information

Ask for more detail from the seller

Contact Supplier2. 50 m3/h/m2 (20 gpm/ft2) for dirty water.

For special water conditions, e.g. iron content and recycled water, other media types

are available at lower flow rates – please consult our service department or your distributor

1. Weekly

2. Monthly

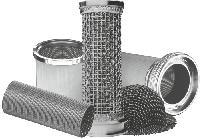

REPLACING THE FILTER’S MEDIA

General Notes :

REPLACING THE FILTER’S MEDIA