Listing ID #4269159

Company Information

Ask for more detail from the seller

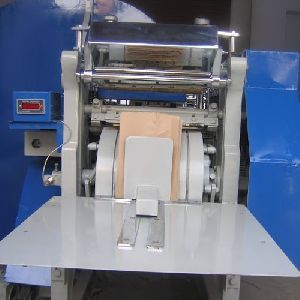

Contact SupplierModern FIBC industry for food grade should be neat and clean, i.e. There should not be any foreign particles OR loose threads or other inside the bags and which is very difficult to clean manually.

For this we offer automatic cleaning M/C by which we can clean the bags from BOTTAM, from TOP and from TOP & BOTTOM respectively.

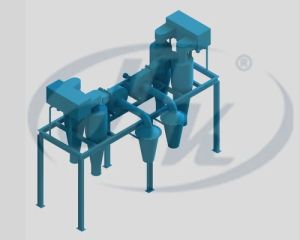

Air is pre filtered with static discharge and is blown through the bag so that all dust and foreign particles settled in the bag should come out of bag. After cleaning the dust and foreign particles like loose thread will be collected in the dust collection box

Which can be easily taken out and the dust collection box is provided with micro filter so that dust should not come out of the dust collection box.

In these machines we provide camera on top and bottom. For we can see the inside of the bag.

Machine is controlled by high-resolution microprocessor controller, which is user friendly by which you can set different operations

The delivery time of the Automatic FIBC cleaning Machine is approximately 30 to 45 days.