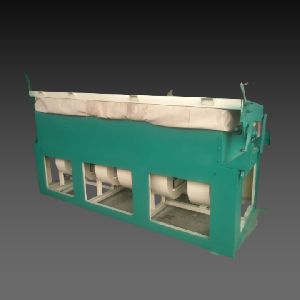

Manufacturers of Psyllium Processing Machinery. Fabricated using high grade material and latest technology, the Psyllium Processing Machinery offered by us are being increasingly. Specification: The machine works in three sections. The first section contains the seeds in it cleans out. The second section, which is used to grind the seeds in it Husk and lali is released in this section This work fully automatic. The third section Husk Cleaning In the box type fan which is separated from husk.

Elevators are highly functional and are have various applications such as vertical lifting of materials such as coffee, rice, food grains and other granular materials. Features: Construction Designed like a construction box with standard length leg sections for easy assembly. Sections It has three sections - top or discharge section, middle or trunk section and the bottom or intake section. The trunk sections can be added or removed to adjust the height of the elevator. Frame It has an all-steel frame for rigidity with cross supports at regular intervals between the legs also doubling as built-in ladders. Belting The belt has been made from white food mounted rubber coated, multi-ply synthetic fiber. Buckets have been attached at regular intervals and run over top and bottom crowned pulleys. Buckets Buckets have been created from deep drawn steel of adequate gauge that is attached to the belt by locking type bolts that sit flush with the belt face. 3 Phase Motor It is provided with an enclosed Imported Italian Gear Motor. All bearings are of the Universal Flange Cartridge type which are known for their lifetime lubrication.

Over the years, we have catered to the voluminous and urgent requirements of our clients from Gujarat(India). We have online payment processing system to avoid security issues. In order to make it more reliable, we have maintained payment logs accessible for the convenience of our customers.

We have a comprehensive set for a totally dust-proof plant which include machinery from 1 ton per hour to 5 ton per hour like primary cleaner, vibro-seperator, de-stoner, gravity separator, cyclone, airlock, and other handling equipment.our machinery are client specific that have found various applications in all commercial cleaning of various grains, spices & seeds. Our machinery are designed to meet challenge of 90% to 99.95 % purity of products.

Destoner Machine

Seed Processing Plant Machinery

Share your thoughts with other customers for KRISHNA INDUSTRIES

Add Review