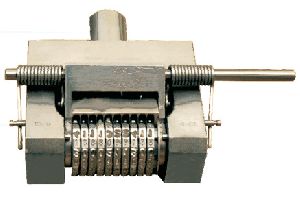

The company is involved in the manufacturing and supplying of highly efficient Manual Rotary Type Numerator . We make available Manual Rotary Type Numerator is different sizes and designs as per the need of the concerned field. Used for marking different components such as steel, aluminum, brass, etc., our Manual Rotary Type Numerator is highly in demand. It is user-friendly and manually operated. Product are Mentioned Below : Perfect time-saver for repeat number by hand stamping. Serial numbers part numbers, or code numbers can be marked on steel, aluminium, brass, etc. Compact design, so it can be carried to mark components. Ideal for steel producers. 'Marking Wheels' can be rotated to any desired position, then locked positively by a locking pin. Individual release : Which means one wheel can be released at a time, without disturbing set-up of other wheels (The locking pin can be pulled to release just that one wheel). No loose parts. The unit is complete, compact and sturdy tool-always ready to use. Wheels made from special Tool Steel, heat-treated for high wear resistance. All Parts treated to remove scale and plated to resist rust. Note : Each ‘Marking wheel’ has 11 face with 0 to 9 figures on 10 faces, and one face blank. Stamping is done by a hammer; and resulting impression is uniform in depth, spacing and alignment of any figure set up. Available on Request : Wheels with alphas instead of figures. Special calligraphy. Also, a shank style Rotary Type Numerator suitable for use on a press. 10 Character per wheel in any desired combination. Bigger character size. High- Precision Stamp Marks : Ellora understands the important role of your logo mark: how it protects your products high reputation; how it says genuine-to safeguard against 'spurious'. Ellora Diehard Marks can match the very best imported stamp marks in every way. Custom-made with total fidelity to every logo. Produced from large scale calligraphy drawings to capture every tiny detail of any logo. High wear-resistance and lasting precision to ensure the longest life of stamp mark. Scientific heat treatment imparted for prolonged service life. Lowest machine downtime because of the stamp mark’s longest life. Our stamp marks achieve a low cost per impression that imported stamp marks. High-Precision Design and Engineering Techniques : Because of calligraphy design techniques, stress concentration is reduced and stamp mark life is increased. Character bevel angles, marking data layout, character depth- all are designed for very lasting precision and clarity. All grinding is done to precise tolerances. Production from master templates ensures the same highly precise data- repeats even for stamp mark orders repeated after a decade! Also available are : But-welded stamps for specially tough applications such as red-hot markings on railway axle, steel billets, etc. Dotted stamp marks for low stress marking. Concaveconvex stamp marks for marking round workpieces. Roller stamp marks for marking on lathes and automates. Long-Life Technology : Made of Tool Steel. Hardened and tempered for high wear-resistance, at the same time retaining toughness. Plated to resist rusting (especially during storage). Roller stamp marks for marking on lathes and automates.