Listing ID #3878195

Company Information

Ask for more detail from the seller

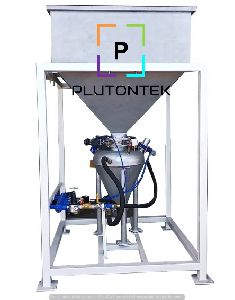

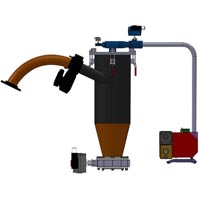

Contact SupplierPneumatic Resonance Conveyor System

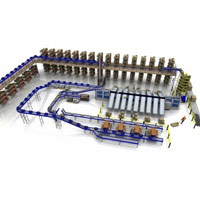

Conveyor systems of the Flexi Link series serve to convey bulk material efficiently and gently.

The feeder system consists of a pneumatic linear vibrator of series NTK, blade springs and the Flexi Link connecting element. This system uses the natural resonance of the springs in order to convey bulk materials. Once the trough starts to vibrate at the resonance frequency, very little additional energy is required to maintain the vibration. Even with varying loads, the trough continues to vibrate in resonance. The amplitude can be adjusted by means of an optional exhaust throttle.

In addition to driving classic feeder troughs, the Flexi Link system can also be used to drive spiral feeders. The blade springs are then arranged in a circle in order to accommodate the spiral feeder.

In addition to the standard versions, customized variants of the Flexi Link series are also available. Furthermore, all components can be supplied separately.

Permissible Operating Conditions:Drive Medium: Compressed air or nitrogen(Filter ≤ 5µm)Preferably with oil mist

Operating Pressure: 2 bar to 6 bar

Ambient Temperature: 5°C to 60°C

Netter Vibration offers the accessories required for the mounting, installation, control and monitoring of vibrators and impactors.

Netter provides solutions. Consult our experienced application technicians