Listing ID #322525

Company Information

Ask for more detail from the seller

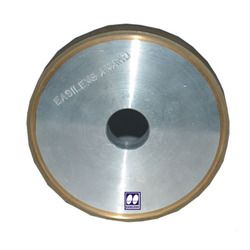

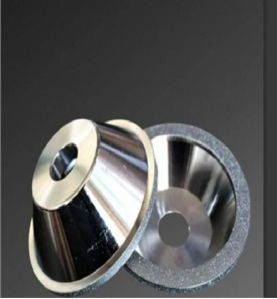

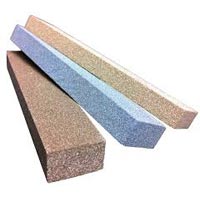

Contact SupplierDiamond / CBN Internal Grinding Wheels can be had in Resin, Metal or Electroplated Bonds. Diamond Internal Grinding Wheels are suited for non ferrous materials machining such as: Tungsten Carbide, Ceramics, Sapphire, Glass, Stones, Fibre Reinforced Plastics etc. CBN Internal Grinding Wheels are usually used for hard ferrous materials over 45 HRC such as High Carbon, High Chrome Steels etc. Resin / Metal Bond Internal Grinding Wheels can be had from minimum 4.0 mm diameter to 40.0mm against specific orders. Electroplated Diamond / CBN Internal Grinding Wheels are available from 1.0mm to 30.0mm diameter in ready stock. Orders for special dimensions can also be executed in shortest time. Recommended Use : Low wheel speed is one of the major causes of poor performance in super abrasive products like Diamond or CBN. Wheel loading and heat build-up are common signs of low RPM. The recommended speed for Electroplated Diamond Internal Grinding Wheel is 2100 to 3600 m/min and for Electroplated CBN Wheel is 3600 to 6000 m/min. The suggested feed vary from 0.005mm to 0.05mm depending on the material ground. Coolant should be used wherever possible, but can be used dry successfully. Diamond Files are offered in the form of Needle Files and in the normal sizes. Machine files also can be supplied against customer's specifications It is available in various shapes like Flat Round Triangle Square Half Round Taper Flat Knife Edge Barrette Slitting The standard size of the needle file is 160mm Overall Length 80mm Coated Length