-

Supply Type

Manufacturer, Supplier

Preferred Buyer From :

All over the world

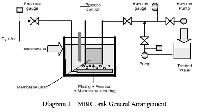

Over the years, there has been an emerging trend in the demand for biopharmaceuticals in the treatment of diseases. Biopharmaceuticals can be produced with microorganisms, adherent cells or suspended....

View More Details