Listing ID #4262091

Company Information

Ask for more detail from the seller

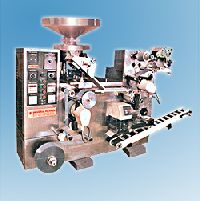

Contact SupplierThe PEW-RP-240 is an automatic Blister Packaging machine utilized for packaging of the tablets, capsules in a blister pack.

This is a machine with continuous operations of forming station, feeding station, sealing station and printing station. Whereas punching station is of intermittent nature. Product capacity of the machine depends on the product characteristics, pack layout and on type of feeding device

Salient Features

1. PVC film is generally used as base film and Aluminum foil with heat sealable VMCH coating as lidding film.

2. Batch code printer, Inspection Camera and Inline perforator are the accessories, which can be mounted on the machine.

3. The blister cavities are formed on the PVC/PVDC film web by vacuum processes.

4. This blister formed web moves over the web guide track and at this station the products are fed into the individual cavities.

5. The formed web along with the tablet or capsules moves towards a sealing station, where it is fused to the aluminum foil, which is drawn from an aluminum reel – feed station

6. The punching tool punches out the specified pack, which is transferred to the out feed conveyor.

7. Products to be packed on the machine are specifically pharmaceutical products such as Tablets and Capsules. Different type of products can be fed into the blister formed cavities on the formed web over the web guide track at the feeding zone

Technical Specification

PEW-RP-240

1. Max. Machine Speed (Packs)4.5-5.5 meters/min{240 packs per minute}

2. Max. Forming Area 110 x 210mm

3. Max. Forming Area 30 x 140mm

4. Optimum Forming Depth 10mm

5. Max Reel Diameter 440mm

6. Max. Lidding Foil 210 mm

7. Max. Core Diameter 70mm Floor Space

8. Machine Width 925 mm

9. Machine Height 1750 mm

10. Machine Length 2900 mm