Company Information

Ask for more detail from the seller

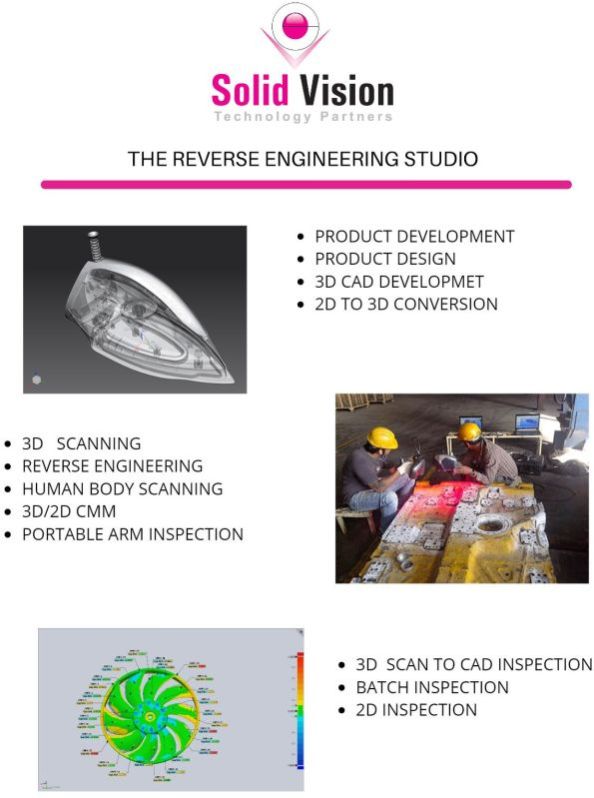

Contact Supplier3D Laser scanners and CMMs are industrial inspection tools that measure the dimensional accuracy of manufactured goods. This is a crucial step to monitoring production quality to ensure large-sized parts meet design specifications for use in critical applications. 3D Scanning for 3D Inspection: 3D scanning is a non-contact technology that captures the complete surface geometry of an object in three dimensions. It offers a plethora of applications for 3D inspection: