Listing ID #4276192

Company Information

Ask for more detail from the seller

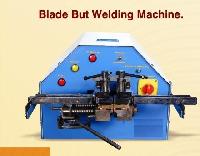

Contact SupplierSterco Band Saw Butt Welder is the result of many years of experience, research and development. It is the most modern method of joining Band Saw Blades giving a joint strength 25% higher than that of the base metal strength. It eliminates the old process of overlapped brazing. Resistance welding is quick and automatic, thus eliminating human error and giving a perfect and strong joint.

WELDING PROCESS

The Band Saw Blades are cut straight exactly at right angles and free of burrs. Welding current, upsetting pressure and upsetting way are set according to the blade width the blade ends being rigidly clamped by special quick acting jaws. By Depressing the welding lever the automatic welding cycle starts. The two ends are heated upto forging temperature in a few seconds, then automatically forged (upset) and current switches off.

|

ANNEALING ATTACHMENT The Upsetting pressure is now turned to annealing and job again clamped properly with extended jaws distance which comes in automatically flipping the the lever to annealing position. By turning the annealing switch on which the heat position are provided the jo is annealed in order to normalize the brittleness in the welded zone. Depending on the type of material, the annealing process must be repeated several times if needed. SHEARING ATTACHMENT Special shearing attachment is provided on the machine itself for cutting the piece at right angles, except for model MB-3 + 4. GRINDING ATTACHMENT The attachment is provided for removing the burrs from the welded zone. This unit is mounted on the machine.

Power Supply |

| Technical Specifications | ||||

| MODEL | MB - 1 | MB - 2 | MB - 3 | MB - 4 |

| Job | Band Saw Blades | Band Saw Blades | Band Saw Blades | Band Saw Blades |

| Welding Capacity | 3 mm to 25 mm | 10 mm to 35 mm | 15 mm to 50 mm | 25 mm to 60 mm |

| KVA Rating | 3 KVA | 5 KVA | 8 KVA | 15 KVA |

| Maximum Primary Current | 13 Amps | 22 Amps | 20 Amps | 37 Amps |