Listing ID #5398069

Ask for more detail from the seller

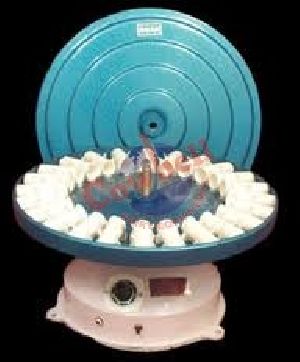

Contact Suppliertypical bottom discharge cycle:

advantages:

material of construction :

note : bottom discharge centrifuge is advised for a non-sticky crystalline product which can be easily cut by the scraper blade.

NSI Equipments Pvt. Ltd. is a well-known name from Meerut (Uttar Pradesh) that is engaged in the production of different kinds of machinery and equipment. We serve as a reliable manufacturer, exporter and supplier (wholesaler & retailer) of industrial plants, sugarcane crusher parts, sugarcane crusher, sorghum crusher, hopper dryer, rotary dryer, rotary vacuum filter, vacuum pan, juice heater, centrifugal machine, industrial evaporator, and industrial crystallizer. We make the equipment available in different specifications to cater to the diverse needs of our customer. We ensure timely-delivery of the products with the aid of swift logistics support and vast distribution channel.

NSI Equipments Pvt. Ltd. was established in the year 1969, and Mr. Lokesh Varshney is the CEO of the organization. He is determined enough to bring forth an exclusive range of equipment that have immense demand in the market. The company’s core business philosophy is to grow while satisfying the patron with premium products and world-class services.

Team

We owe our success to our dedicated team of engineers and other skilled labourers. They work in harmony to offer quality process plants and equipment in stipulated time frame. We work as a team and our engineers work hard to fabricate plants and equipment in different capacities.

Why Us

Owing to our expertise in this field, we have been able to provide the clients with a comprehensive and quality range of Mini Sugar Plants, Sugar Mill Plants, Hydraulic Sugar Cane Crusher. Some of the other factors for which our clients give preference to us are as follows:

Clientele

Our uncompromising attitude towards quality products and services has enabled us to serve our clients in the best possible manner. We have supplied more than 300 plants in India and exported abroad countries like USA, Egypt, Indonesia, Kenya, Tanzania, Russia, Mauritius, Bangladesh, Zambia etc.