Listing ID #5016450

Company Information

Ask for more detail from the seller

Contact SupplierProduct Description:

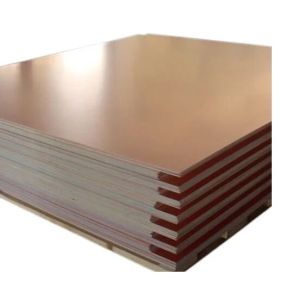

Copper Laminated Busbars comprise flexible laminated copper connections that are produced using highly conductive electrolytic grade copper foil & sheets. These laminated Busbars undergo press welding where individual copper strips are fused through applying direct current as well as pressure, which results in ensuring minimum resistance as well as in enhancing the product life as well as in the reduction of downtime.

Further, these also feature superior mechanical & electrical properties at higher temperatures. These also feature higher power density as well as better electromagnetic compatibility (EMC).

Laminated Busbar is applied to implementing the connection of power devices in electric and electronic products. Through the parallel and laminated structure of the positive and negative electrodes, the inductance distributed among the circuit is reduced, which helps reduce the peak reverse voltage of both ends of the power elements and lower the requirements of voltage protection and circuit absorbing. This structure is aimed at improving the reliability and stability of power devices and the circuit integration for easier repair and maintenance.

Laminated Busbar could be customized or specified according to your design or drawings. It also could be designed and developed according to your application and requirements. We are making various types of Profile busbars . These busbars are produced on Fibre optic laser machine and water jet cutting machine to get the required profile and accuracy .