Company Information

Ask for more detail from the seller

Contact SupplierBacked by a team of experienced engineers, we are known for offering precisely designed Ice Block Making Plant. Using latest technology, we Manufacture, Export and Sup ply high performance Ice Block Making Plant that is highly appreciated for its energy efficiency, easy to install feature and long service life. Passed on all quality parameters, we make sure that only best and cost-effective Ice Block Making Plant reaches our buyers. We always deliver on time.

Description

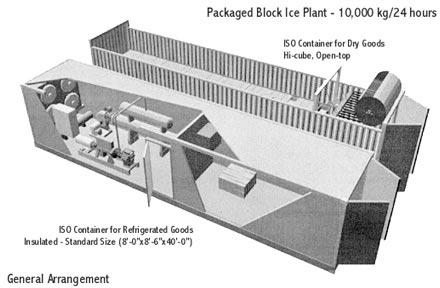

The Ice Making & Harvesting section of the plant consists of the Brine Tank, an electrically operated Lifting Device (Crane) running on rails along the sides of the tank, a Thawing Tank, a Tilting Device with an inclined Wooden Table to receive the ice blocks as they slide out of the cans and a Filler. Standard Rectangular 25,50 & 150 kg Ice Cans, the brine tank is covered with solid Wooden Lids as shown on the picture.

The Machine Room occupies the rear, the Machine Room accommodates the Brine Chiller with the Liquid Separator, the Brine Recirculation Pump, the Air or water Cooled Condenser, the Refrigerant Receiver, the Electric Switch Board, and other accessories which are connected to one another through refrigerant and brine piping as shown on the Piping Diagram and the electrical wiring. Cold pips and vessels are insulated as required.

The refrigerant evaporating in the Brine Chiller cools the brine - the cold carrier - which is recirculated by the Brine Pump from the Brine Tank through the Brine Chiller and back to the Brine Tank. The recirculated quantity is sufficient to facilitate adequate agitation in the Brine Tank. Removal of the process heat takes place in the Air or water Cooled Condenser. Liquid refrigerant collects in the Liquid Receiver, from where it passes over an expansion device back to the Brine Chiller.

The refrigeration capacity required to maintain the temperature in the Ice Storage is small compared to that of the Block Ice Plant. Therefore, to simplify design and minimize service and maintenance work, the Ice Storage is cooled with an Air Cooler refrigerated through brine pumped from the Brine Tank, for which a small brine pump is provided.

The two main sections of the plant, namely the Ice Making & Harvesting and the Machine Room & Ice Storage , are placed side by side on the installation site and interconnected by the Supply and Return Lines for the brine and Electric Power Supply for Harvesting and Lighting.