Company Information

Ask for more detail from the seller

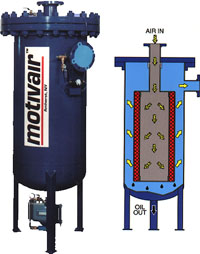

Contact SupplierAll lubricated industrial air compressors discharge oil mist into the compressed air system they serve. Motivair Mist Eliminators are deep-bed coalescing filters, designed for removing this compressor oil, plus condensed moisture and dirt from compressed air systems. Their exceptionally long element life and low pressure-drop make Motivair Mist Eliminators especially suitable for installation at the point of compression. They are an ideal back-up, in the event of a ruptured oil separator in a screw compressor, and will prevent compressor oil from flooding the piping system.

The deep element bed of woven fibers has an exceptionally high dirt holding capacity, while providing highly efficient oil removal. Using a combination of Direct Interception, Inertial Impaction & Brownian Motion, Mist Eliminators remove up to 99.999% of all 1-3 micron particles and 99.98% of all 0.1 micron particles. Housings are fabricated in carbon steel (stainless on request) with an internal epoxy lining to inhibit corrosion. All models are ASME stamped, and are finished in high quality enamel paint.

Compressed air enters the Mist Eliminator through the top inlet connection. Due to the very large surface area & low velocity, the compressed air is evenly distributed through the deep filter bed, with both aerosols and solid particles are effectively removed. The contaminants accumulate in the bottom of the housing, and are removed by an (optional) automatic drain valve. The clean air flows upwards around the outside of the element and exits through the horizontal outlet connection.