Company Information

Ask for more detail from the seller

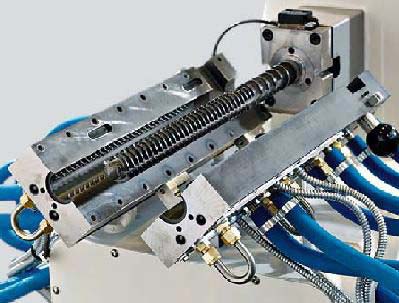

Contact SupplierRelying on our know-how in the industry gained over years, we, as a Manufacturer and Supplier of Single Screw Reciprocating Extruder (PCS 46) have put us in the top band of the industry. It can be easily cleaned in a short time span. Our customers can also save their costs as it consumes less heat and power. It also takes lesser time and energy in case of a power failure.

Advantages

Disadvantages