Listing ID #5160883

Company Information

Ask for more detail from the seller

Contact SupplierWhat is a Split Butterfly Valves?

What are the benefits of using SBV Technology?

What is Containment ?

Measuring containment?

Advantages provide by DAS Valves

Design Feature

Valves are designed to help you improve the three key elements of overall equipments effectiveness (OEE)

Safety Interlocks

Benefits

Industrial application

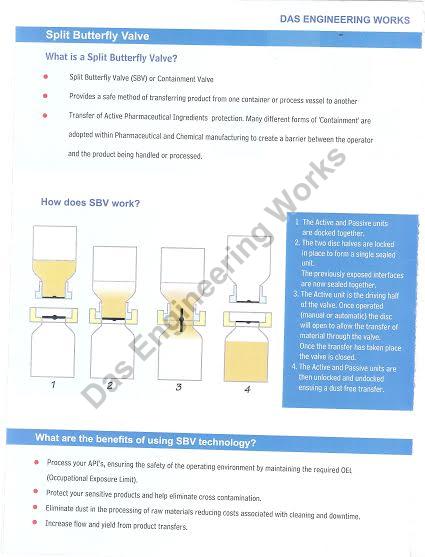

How Does SBV Works?

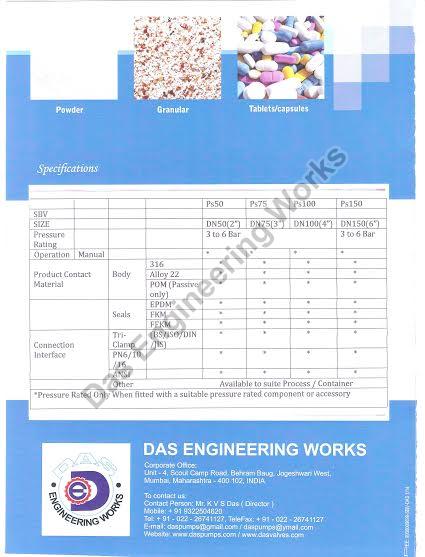

| SBV | - | - | - | PS50 | PS75 | PS100 | PS150 | PS200 |

|---|---|---|---|---|---|---|---|---|

| Size | - | - | - | - | - | - | ||

| Pressure rating | - | - | - | DN50 (2*) | DN75)3*) | DN100(4*) | DN 150 (6*) | DN 200 (8*) |

| Operation | Manual | - | - | 3 TO 6 BAR | 3 TO 6 BAR | |||

| Product contact Material | Body | 316 | * | * | * | * | * | |

| Alloy 22 | * | * | * | * | * | |||

| POM( Passive Only) | * | * | * | * | * | |||

| Seals | EPDM | * | * | * | * | * | ||

| FKM | * | * | * | * | * | |||

| Silicon | * | * | * | * | * | |||

| Connection Interface | Tri clamps | (BS/ISO/DIN/JIS) | * | * | * | * | * | |

| PN6/10/16 | * | * | * | * | * | |||

| ANSI | * | * | * | * | * | |||

| Other | Avaiable to suite Process/ container | |||||||

| Pressure rated only when fitted with a suitable Pressure rated component or accessory | ||||||||