Listing ID #4565638

Company Information

Ask for more detail from the seller

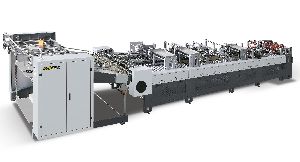

Contact SupplierOur variety of seal machines include food packaging machine, liquid packaging machine, spices packaging machine, milk powder packaging machine and many more.

Application: Tea, Green Tea, Herbal Tea etc.

| Features | Advantages | Benefits |

| Intermittent Motion Machine | Efficient, effective packing | Savings on wastage |

| Machine is mechanically cam operated. | Machine is centrally controlled, Has digital display | System runs in Synchronization |

| Operator Friendly / Low | Easy to Operate/Less Servicing | High Run Time / Increased |

| Maintenance Machine | Required | Productivity |

| Stainless steel contact parts | No rusting | Long Life |

| Machine is castor mounted | Ease of installation and shifting | Savings On labor |

| Batch Coding Device | To print M.R.P, Month of packing, Lot No. Etc. | Helps in detecting manufacturing and expiry date. |

| Machine is equipped with PID | Displays / controls Sealing Temperature of Sealers | Optimum Temperature for Sealing / Better Sealing |

| Photo cell registration Unit (Reads the photocell mark) | To seal and perforate the pouch at right length | Pouch printed layout in place, consistency in pouch size, |